Toyota Head Gasket Problems: Symptoms, Causes, and Solutions

Your Toyota’s engine has a critical component that works hard. The head gasket is a thin barrier between the engine block and cylinder head. It handles high pressures and temperatures every time you start your car.

If this seal fails, it leads to serious Toyota engine problems. The gasket must handle intense heat and prevent coolant and oil from mixing with combustion gases.

Spotting blown head gasket symptoms early can save you a lot of money. Many Toyota owners miss these signs until it’s too late. This guide will help you spot these symptoms fast and understand your options.

Whether you’re facing overheating or coolant loss, knowing about head gasket repair helps you make informed choices about your car’s future.

Key Takeaways

- Head gaskets seal cylinders and prevent fluid leaks in your Toyota engine

- Early detection of symptoms can prevent costly engine damage

- Common warning signs include overheating, coolant loss, and white exhaust smoke

- Professional diagnosis is essential before attempting any repairs

- Repair costs vary significantly based on engine type and damage extent

- Prevention through regular maintenance extends gasket lifespan

Understanding Toyota Head Gaskets and Their Critical Role

Inside your Toyota’s engine, a small but vital part works hard. The head gasket is not just a simple piece of material. It’s a key player in your vehicle’s performance, facing extreme conditions.

The head gasket’s main job is to seal several important areas. It sits between the engine block cylinder head assembly. This is where your engine’s pistons and cylinders are, along with valves, spark plugs, and camshafts.

The head gasket is like your engine’s ultimate multitasker. It keeps engine oil and coolant separate, preventing a disaster. It also stops coolant from getting into the combustion chambers, where it could harm your engine. Most importantly, it keeps the combustion chamber seal tight, ensuring pressure stays where it should.

The head gasket faces incredible heat and pressure. Temperatures can soar over 2,000 degrees Fahrenheit during combustion. The pressure changes are constant and strong, with each firing cycle adding to the force. Your engine also expands and contracts as it heats up and cools down.

The head gasket’s work affects your Toyota’s performance and reliability. When it seals well, your engine runs smoothly and efficiently. It keeps oil and coolant separate, allowing them to do their jobs right. Without these seals, your engine could be severely damaged.

Knowing how the engine block cylinder head works helps you see why head gasket issues are so critical. This part must seal multiple surfaces perfectly, all while handling extreme temperatures and pressures. If it fails, many engine systems are at risk, making quick action necessary for your Toyota’s health.

Recognizing Early Warning Signs of Head Gasket Failure

Your Toyota’s engine sends clear warning signals before head gasket failure becomes catastrophic. Learning to identify these head gasket failure symptoms early gives you time to address problems before they turn into expensive repairs. Most Toyota owners can spot these warning signs with basic observation skills.

The key to preventing major engine damage lies in understanding what your vehicle is trying to tell you. These symptoms rarely appear overnight. Instead, they develop gradually over weeks or months, giving attentive drivers plenty of opportunity to take action.

Temperature Gauge Changes and Heat Issues

A Toyota overheating engine often serves as the first red flag for head gasket problems. Your temperature gauge becomes your best friend when monitoring engine health. Watch for readings that climb higher than normal, even during routine driving.

Pay attention to these specific overheating patterns:

- Rapid temperature spikes during highway driving

- Consistent running hotter than the normal range

- Temperature fluctuations that seem random or unexplained

- Steam or vapor rising from under the hood

Your cooling system works harder when head gasket integrity fails. This extra strain causes temperatures to rise beyond safe operating levels. Don’t ignore even minor temperature increases, as they often signal developing problems.

Fluid Loss and Color Changes

Monitoring your coolant tells a story about your engine’s internal condition. Coolant leak signs extend beyond simple puddles under your car. Internal leaks can be just as serious as external ones.

Check for these coolant-related warning signs:

- Mysterious coolant loss with no visible leaks

- Milky or muddy appearance in the coolant reservoir

- Oil that looks creamy or chocolate-colored

- Bubbling in the radiator when the engine runs

When head gaskets fail, coolant and oil can mix together. This creates the telltale milky appearance that experienced mechanics recognize immediately. Regular fluid checks help you catch these changes early.

Exhaust Smoke Patterns

White smoke from your tailpipe provides another critical clue. Normal condensation creates light vapor that disappears quickly. Head gasket problems produce thick, persistent white smoke that continues even after your engine warms up.

Distinguish between normal and problematic exhaust smoke:

- Normal: Light vapor on cold mornings that disappears within minutes

- Concerning: Thick white smoke that persists during warm weather

- Serious: Sweet-smelling white smoke that indicates coolant burning

This white exhaust smoke happens when coolant enters the combustion chamber through damaged head gasket seals. The burning coolant creates distinctive white clouds that experienced Toyota owners learn to recognize. Trust your instincts if the exhaust smoke seems unusual or excessive.

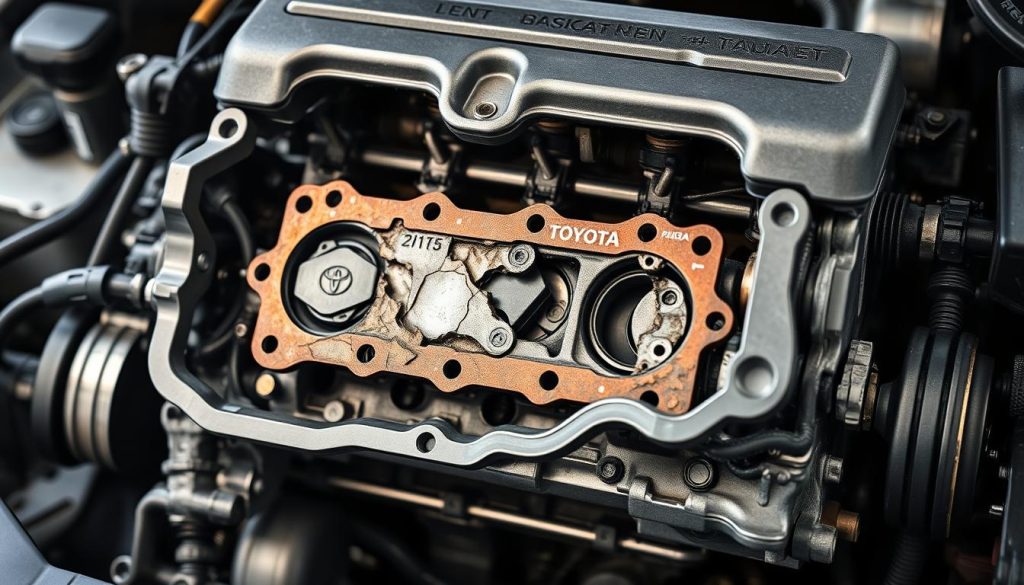

Most Common Toyota Head Gasket Problems

When Toyota head gaskets fail, they show specific damage patterns. These patterns affect how well the engine works. Mechanics can quickly spot these problems because they follow certain paths.

Toyota owners often face three main head gasket issues. Each issue has its own symptoms and repair needs. Knowing these patterns helps you talk better with your mechanic and make smart repair choices.

The severity of these problems depends on how long they’ve been there. Catching them early makes repairs cheaper and easier. Waiting too long can lead to a costly engine rebuild.

Internal Coolant Leaks

An internal coolant leak happens when coolant gets into the engine’s cylinders. This mix of coolant and fuel in the cylinders causes thick white smoke from the exhaust. The smoke smells sweet.

When coolant gets into the cylinders, your engine runs rough. The spark plugs can’t ignite the fuel-coolant mix. This leads to misfiring, less power, and damage to other engine parts.

Internal leaks also mix with your engine oil. The oil becomes milky or frothy when mixed with coolant. This makes it lose its lubricating power. If not fixed fast, it can destroy your engine.

External Coolant Seepage

External seepage is when coolant leaks out of the engine. You’ll see coolant and oil streaks on the engine block. These signs are easier to spot than internal leaks.

The leak usually shows where the head meets the engine block. Look for dried coolant residue around this area. Fresh leaks will have wet spots or dripping when the engine is warm.

External leaks start small but grow over time. The constant heating and cooling cycles weaken the gasket. This lets more coolant escape, leading to overheating problems.

Compression Loss Issues

Compression loss happens when the head gasket fails between cylinders or between a cylinder and the cooling system. This lets pressurized gases escape during compression. Your engine loses power and efficiency.

A compression test Toyota mechanics do shows uneven pressure readings. Normal engines have consistent pressure across all cylinders. Failed head gaskets cause big pressure differences that are easy to spot.

You’ll notice your car doesn’t accelerate well and idles roughly when compression drops. The engine works harder to get the same power. This makes fuel economy worse because the engine can’t burn fuel well.

Severe compression loss can damage cylinder walls and pistons. The escaping gases carry oil and fuel particles that score metal surfaces. This damage often means you need a complete engine rebuild, not just a new head gasket.

Step-by-Step Visual Inspection Guide

Learning to check your Toyota’s key systems yourself is empowering. It helps you spot head gasket issues early. These simple checks need no special tools and can save you from expensive surprises later. Regular visual inspections take just minutes but provide valuable insights into your engine’s health.

Before starting any inspection, make sure your engine is cool and parked on level ground. Never check hot engine components, as this can cause serious burns. Keep a flashlight handy for better visibility in darker engine compartments.

Checking Your Coolant Reservoir

The coolant reservoir inspection is key to your Toyota coolant check routine. Start by finding the translucent plastic tank near your radiator, usually marked with minimum and maximum fill lines.

Healthy coolant should appear clear or slightly colored (green, orange, or pink depending on your Toyota’s specifications). Look for these warning signs that suggest head gasket problems:

- Milky or cloudy appearance indicating oil contamination

- Rust-colored particles floating in the coolant

- Oily film on the coolant surface

- Unusual bubbling when the engine runs

Check the coolant level with the engine cold. If you notice frequent coolant loss without visible external leaks, this often points to internal head gasket failure. The coolant may be burning off through the combustion chamber.

Pay attention to any sweet smell around the reservoir area. This distinctive odor often accompanies coolant leaks and can help you identify problems early.

Inspecting Engine Oil for Contamination

Your engine oil inspection provides critical clues about head gasket integrity. Remove the oil dipstick when the engine is warm but not hot for the most accurate reading.

Normal engine oil should appear amber to black and flow smoothly off the dipstick. The telltale sign of head gasket failure is milky, foam-like oil that resembles chocolate milk or coffee with cream.

| Oil Appearance | Condition | Action Required |

|---|---|---|

| Clear amber to dark brown | Normal, healthy oil | Continue regular maintenance |

| Milky or foamy texture | Coolant contamination | Stop driving, seek immediate repair |

| Metal particles visible | Severe engine wear | Professional diagnosis needed |

| Thick, tar-like consistency | Overdue oil change | Change oil immediately |

Check the oil cap as well. Remove it carefully and examine the underside for white, creamy deposits. These formations indicate coolant mixing with oil due to head gasket failure.

If you discover contaminated oil, avoid driving your Toyota until professional repairs are completed. Continuing to operate the engine can cause catastrophic damage.

Examining Exhaust Smoke Patterns

Proper exhaust smoke diagnosis helps distinguish between normal operation and head gasket problems. Start your Toyota and observe the exhaust pipe from a safe distance behind the vehicle.

White smoke that persists after engine warm-up indicates coolant burning in the combustion chamber. This differs from normal water vapor that disappears quickly on cold mornings.

Here’s what different smoke colors typically indicate:

- Thick white smoke: Coolant leaking into cylinders (head gasket failure)

- Blue smoke: Oil burning (worn rings or valve seals)

- Black smoke: Rich fuel mixture (carburetor or injection issues)

- Clear vapor: Normal water condensation

The white smoke from head gasket failure often has a sweet smell and continues even after the engine reaches operating temperature. You might also notice the exhaust smoke increases when accelerating or under load.

Watch for unusual exhaust patterns during different driving conditions. Intermittent white smoke during highway driving or heavy acceleration can indicate minor head gasket seepage that worsens under pressure.

Document your findings with photos or videos to share with your mechanic. This visual evidence helps professionals understand the problem’s severity and plan appropriate repairs.

Professional Diagnostic Testing Procedures

When you see signs of head gasket trouble, it’s time for a professional check. These tests give clear answers beyond what you can see. Mechanics use special tools to get detailed info about your Toyota’s engine.

Three main head gasket diagnostic methods help find problems accurately. Each test looks at different parts of the head gasket. Knowing about these tests helps you understand what your car needs.

Performing a Compression Test

A Toyota compression test checks how much pressure each cylinder makes. Mechanics take out the spark plugs and put in a gauge. They crank the engine to get the highest pressure readings.

Normal pressure is between 140 to 200 PSI for most Toyotas. Big differences between cylinders mean head gasket trouble. If one cylinder is way off from the others, it could be a problem.

Low pressure in nearby cylinders often means a head gasket leak. This test finds leaks inside the engine. Mechanics compare your car’s pressure to what the maker says it should be.

Coolant System Pressure Testing

The coolant pressure test uses a pump to pressurize your car’s cooling system. They attach the tester to the radiator or reservoir. The system gets a bit more pressure than usual.

A good cooling system keeps steady pressure. If pressure drops fast, there’s a leak. Leaks show up on hoses, radiator, or water pump during this test.

Leaks in the head gasket cause pressure to drop without showing outside. The leak lets pressure into the engine’s chambers. This test finds both inside and outside leaks.

Chemical Block Test Method

The chemical block test looks for engine gases in the cooling system. Technicians remove the cap and add a test kit to the reservoir. If gases are there, the fluid changes color.

This head gasket diagnostic method proves leaks inside. Gases can only get in through a broken head gasket. The reaction happens fast when gases are found.

Shops often use this test to confirm repairs. Positive results mean no doubt about the head gasket. This test works even when symptoms are unclear or come and go.

| Diagnostic Test | Purpose | Normal Results | Problem Indicators |

|---|---|---|---|

| Compression Test | Measures cylinder pressure | 140-200 PSI consistent | Low or uneven readings |

| Coolant Pressure Test | Detects cooling system leaks | Steady pressure maintained | Rapid pressure loss |

| Chemical Block Test | Identifies combustion gases | No color change | Fluid changes color |

| Combined Results | Confirms diagnosis | All tests pass | Multiple test failures |

Professional testing removes doubt about head gasket issues. These tests give solid evidence for fixing your car. Accurate diagnosis avoids unnecessary repairs and finds the real problem.

Good shops do many tests to be sure. This careful approach protects everyone. Knowing about these tests helps you ask better questions during the check-up.

Root Causes of Toyota Head Gasket Failures

Toyota head gasket failures don’t happen overnight. They develop from specific conditions that every owner should understand. Knowing these Toyota head gasket causes helps you spot problems early and make smart decisions about repairs. Most failures stem from three main factors that affect your engine’s delicate sealing system.

Heat, age, and design flaws create the perfect storm for gasket breakdown. Each cause damages your engine differently, but all lead to the same expensive result. Understanding these root causes empowers you to protect your investment and avoid costly surprises.

Thermal Stress and Heat-Related Damage

Engine overheating damage ranks as the number one killer of head gaskets in Toyota vehicles. When your engine runs too hot, metal components expand beyond their design limits. The cylinder head and engine block grow at different rates, creating stress that overwhelms the gasket’s sealing ability.

Extreme temperatures cause the head gasket material to break down rapidly. Detonation occurs when fuel ignites incorrectly, creating pressure spikes that damage the gasket’s armor rings. These protective elements normally contain cylinder pressure, but heat stress makes them brittle and prone to cracking.

Coolant system failures often trigger this destructive cycle. A stuck thermostat, failed water pump, or clogged radiator creates hot spots that warp metal surfaces. Once warping begins, the head gasket cannot maintain proper sealing pressure between surfaces.

Temperature warning lights demand immediate attention to prevent engine overheating damage. Continuing to drive with an overheating engine guarantees head gasket failure and potentially destroys the entire motor. Smart Toyota owners pull over immediately when temperature gauges climb into the red zone.

Wear Patterns in Aging Vehicles

High mileage Toyota problems often center around natural gasket deterioration over time. Head gaskets contain multiple layers of materials that gradually lose their sealing properties. Steel core gaskets develop micro-cracks that allow combustion pressure to escape into cooling passages.

Vehicles with over 150,000 miles face increased risk of gasket failure regardless of maintenance history. The constant heating and cooling cycles create fatigue in gasket materials. Thermal cycling causes expansion and contraction that eventually breaks down even the highest quality gaskets.

Oil contamination accelerates aging in older Toyota engines. Dirty oil carries abrasive particles that score cylinder head surfaces. These microscopic scratches create leak paths that compromise gasket integrity over time.

Regular maintenance extends gasket life but cannot prevent age-related failure indefinitely. High mileage Toyota problems require proactive monitoring. Catching early signs prevents catastrophic engine damage that costs thousands more than preventive replacement.

Manufacturing and Design Vulnerabilities

Certain Toyota models suffer from known design weaknesses that increase head gasket failure rates. Some engines use gasket materials that cannot handle the thermal stress of modern driving conditions. Multi-layer steel gaskets replaced older composite designs but created new challenges in specific applications.

Bolt torque specifications play a critical role in gasket longevity. Under-torqued head bolts allow movement between surfaces that damages gaskets prematurely. Over-torquing creates stress concentrations that crack cylinder heads or strip bolt threads.

Engine block and cylinder head materials must expand at compatible rates to maintain proper sealing. Some Toyota engines pair aluminum heads with iron blocks, creating thermal expansion mismatches. This design choice reduces weight but increases stress on head gaskets during temperature changes.

Quality control issues during manufacturing occasionally produce defective gaskets that fail early. These problems typically surface within the first 50,000 miles and may qualify for warranty coverage. Documented patterns of premature failure sometimes trigger manufacturer recalls or extended warranty programs.

| Failure Cause | Primary Symptoms | Typical Mileage Range | Prevention Strategy |

|---|---|---|---|

| Engine Overheating | White smoke, coolant loss, temperature spikes | Any mileage | Monitor cooling system, replace thermostat regularly |

| High Mileage Wear | Gradual coolant consumption, oil contamination | 150,000+ miles | Proactive replacement, quality oil changes |

| Design Issues | Early failure, recurring problems | Under 100,000 miles | Research model history, warranty claims |

| Installation Errors | Immediate leaks, uneven wear patterns | Shortly after repair | Choose experienced technicians, proper torque specs |

Understanding these Toyota head gasket causes helps you make informed decisions about maintenance and repairs. Each failure mode requires different prevention strategies and repair approaches. Working with experienced technicians who understand these patterns ensures proper diagnosis and lasting repairs.

Prevention remains far more cost-effective than repair when dealing with head gasket problems. Regular cooling system maintenance, quality oil changes, and immediate attention to warning signs protect your engine investment. Smart Toyota owners learn to recognize early symptoms and take action before minor issues become major expenses.

Toyota Models With Known Head Gasket Issues

Knowing which Toyota models are more likely to have head gasket problems helps owners take better care of their cars. Toyota makes reliable engines, but some models have more head gasket issues. These problems depend on the engine design and when the car was made.

Head gasket problems vary across Toyota’s models. Some engines are more prone to issues because of their design. Others face problems due to when they were made or the materials used. Spotting these patterns helps owners stay ahead of any issues.

Generation-Specific Problems in Popular Models

The Toyota Camry head gasket issues often show up in certain years. The 2007-2011 Camry models with 2.4L engines have higher failure rates. This is because they run hotter, putting more stress on the head gasket seals.

Camry owners should watch for signs like coolant loss and white smoke at cold starts around 100,000 miles. Regular cooling system maintenance is key to avoid expensive repairs.

The 2012-2017 Camry models have better head gasket durability. But, they also need more frequent coolant changes and temperature checks in summer.

Compact Model Reliability Concerns

Toyota Corolla engine problems with head gaskets often happen in 2009-2013 models. The 1.8L engine in these cars uses a material that gets brittle over time. This leads to slow leaks, not sudden failures.

Corolla owners might see small coolant puddles before major symptoms appear. The engine design makes leaks easy to spot, giving owners a chance to act early. Catching these leaks early prevents engine damage and saves money on repairs.

The 2014 and newer Corolla models have better head gasket designs. But, regular maintenance is vital for all Corolla generations.

“The key to preventing head gasket failure in any Toyota model is maintaining proper coolant levels and addressing overheating issues immediately.”

Hybrid System Unique Considerations

The Toyota Prius head gasket faces special challenges due to its hybrid design. The engine’s start-stop cycles cause temperature changes that stress head gasket seals. This can lead to faster wear in high-mileage vehicles.

Prius models from 2004-2009 have the highest head gasket failure rates. The early hybrid system design creates unique thermal stresses when switching between electric and gas power. Owners should check coolant levels more often than in regular cars.

The hybrid system makes diagnosis tricky. Engine temperature readings can be misleading because of the electric motor. This makes getting a professional diagnosis important for Prius owners.

| Toyota Model | High-Risk Years | Common Symptoms | Typical Mileage |

|---|---|---|---|

| Camry | 2007-2011 | Coolant loss, white smoke | 90,000-120,000 |

| Corolla | 2009-2013 | External leaks, overheating | 100,000-140,000 |

| Prius | 2004-2009 | Temperature fluctuations | 150,000-200,000 |

| RAV4 | 2009-2012 | Coolant contamination | 120,000-160,000 |

Prevention strategies need to match the model’s specific needs. Camry owners should focus on cooling system care. Corolla owners should watch for leaks. Prius owners need to know about hybrid system care.

Getting a professional diagnosis is key when symptoms show up in any Toyota model. Each model has its own set of challenges that require specific tests and repairs. Knowing your car’s specific needs helps you work well with service providers and make smart repair choices.

How to Choose Between Repair and Replacement Options

Choosing between repairing or replacing your Toyota’s head gasket is a big decision. It depends on your car’s condition, repair costs, and how much it’s worth in the long run. Knowing your options helps you decide what’s best for your budget and needs.

Several things affect whether fixing your Toyota is worth it. The age, mileage, and condition of your car are key. Also, the head gasket replacement cost must be compared to your car’s value and reliability in the future.

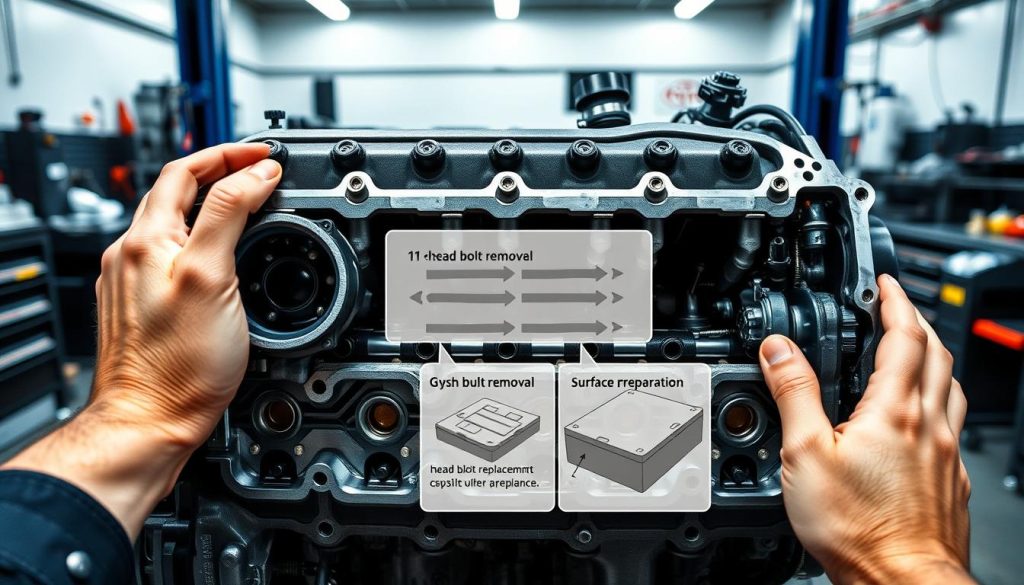

Complete Head Gasket Replacement Process

Replacing a head gasket means taking apart the engine, which needs a pro and special tools. The first step is draining all fluids and removing the cylinder head from the engine block. Professional technicians should handle head gasket repairs because of the complexity and precision needed.

The replacement process includes important steps for reliability. Technicians check the cylinder head for warping or cracks that could affect the new gasket. Making sure the surface is smooth is critical, as small imperfections can cause problems later.

Choosing quality replacement gaskets is important. Many aftermarket options are better than factory parts. But, the way the gasket is installed is more important for lasting results.

A head gasket replacement done right the first time will last the life of the engine, but shortcuts in the process often lead to repeat failures within months.

Engine Rebuild Evaluation

Head gasket failure might mean deeper engine problems that need fixing. A Toyota engine rebuild might be needed if cylinder walls are worn or other parts are damaged. Your mechanic should check these things during the first diagnosis.

Thinking about engine rebuilds goes beyond just the head gasket. Worn pistons, damaged valves, or bearing issues often come with head gasket failures in older cars. Fixing these problems together can be more cost-effective than doing them separately.

Deciding between a partial or complete engine rebuild depends on your car’s condition. Partial rebuilds focus on the top end while complete rebuilds fix everything inside. Your mechanic’s advice will help make this choice.

Cost-Benefit Decision Making

Creating a plan for your repair vs replace decision is key to making a smart financial choice. Think about both the upfront costs and the long-term effects of your choice. Here’s a table to help you compare:

| Decision Factor | Repair Option | Replace Option | Weight in Decision |

|---|---|---|---|

| Immediate Cost | $1,500-$4,000 | $15,000-$35,000 | High |

| Vehicle Age | Best under 10 years | Any age acceptable | Medium |

| Expected Reliability | Good with quality repair | Excellent with new vehicle | High |

| Resale Value Impact | Moderate decrease | No impact with new car | Medium |

Your personal situation affects the best choice for you. Consider the head gasket replacement cost against buying a new car. Think about insurance, registration, and financing costs when comparing total costs.

How attached you are to your car also matters. Many Toyota owners choose to repair their cars because they’re reliable and well-maintained. Emotional factors deserve consideration alongside financial calculations in your final choice.

Time is another factor. Head gasket repairs take a few days, while buying a new car can happen right away with the right financing. Think about your transportation needs during the repair time when deciding.

Professional Repair Procedures and What to Expect

Letting professionals handle your Toyota’s head gasket repair is a thorough process. It aims to make your engine reliable again. The Toyota head gasket repair process is strict, ensuring quality and lasting results. Knowing each step helps you trust the repair and understand what’s happening.

Experts tackle head gasket repairs with a detailed plan. They use their experience and proven methods for the best results for your car.

Pre-Repair Inspection Steps

Before starting any professional engine repair, a detailed inspection is done. This step is key to avoiding surprises and getting accurate repair quotes.

The inspection covers several important areas:

- Engine block and cylinder head examination for warping or cracks

- Cooling system pressure testing to find all leaks

- Oil contamination analysis to see internal damage

- Compression testing across all cylinders

- Exhaust gas analysis to check the combustion chamber

Technicians also check the radiator, water pump, and thermostat. These parts often need work when head gasket issues arise.

Head Gasket Replacement Timeline

The head gasket replacement time depends on your Toyota model and the damage found. Most repairs take 8 to 16 hours, spread over a few days.

Day one is for engine disassembly and initial check. Technicians remove parts and document their findings. Day two is for machine shop work, where the cylinder head is resurfaced.

The last step is reassembly with new gaskets and seals. Shops take their time to ensure everything is done right, as proper torque and timing are key.

Quality Control and Testing

Professional shops follow strict quality control during the Toyota head gasket repair process. These steps ensure your repair meets standards and specifications.

After the repair, testing includes:

- Initial startup procedures with careful temperature monitoring

- Pressure testing to check seal integrity

- Test drive evaluation under different conditions

- Final inspection of all fluid levels and connections

Good shops provide detailed records of all work done. They also offer warranties, showing their confidence in their work and giving you peace of mind.

Temporary Solutions and Emergency Measures

When your Toyota’s head gasket fails, quick fixes can give you time to plan repairs. These fixes aren’t permanent but can help you avoid being stuck or give you time to save money. Knowing your options helps you make smart choices when things get tough.

Emergency repairs work best if done early. Remember, these solutions have limits and shouldn’t replace professional fixes. Temporary fixes are like bridges, not final solutions.

Head Gasket Sealer Products

Head gasket sealer products can help, but their success depends on the damage. These chemicals expand and harden when they meet combustion gases. They can seal small cracks and minor breaches in the head gasket.

Liquid sealers are common and can be found at auto parts stores. Pour them into your radiator when it’s cool. The product will circulate through your cooling system and find leak points.

Success rates vary based on the damage. Minor leaks do better than major ones. Expect relief for weeks to months.

Brands like BlueDevil, Bar’s Leaks, and K-Seal are popular. Always follow the instructions and don’t use them on overheated engines. Make sure your Toyota is cool before applying.

Cooling System Flush Procedures

Flushing your Toyota’s cooling system can help by removing debris that worsens head gasket issues. This process cleans out old coolant and particles. Fresh coolant also helps with heat transfer.

Start by draining the old coolant from your radiator and engine block. Use distilled water to rinse the system several times. This removes oil and combustion byproducts.

Fill the system with new coolant that matches Toyota’s specs. Always use the correct coolant type for your model year. Run the engine and check for proper circulation.

Keep an eye on coolant levels after flushing. Head gasket damage may cause coolant loss. Note any changes in fluid levels or colors.

When Temporary Fixes Are Appropriate

Use temporary solutions in certain situations. They’re good when you need to get around while fixing your car. They’re also useful when you can’t afford major repairs right away.

Avoid temporary fixes if your engine overheats a lot or if you see white smoke or rapid coolant loss. These signs mean you need professional help right away.

Think about your car’s value when choosing temporary fixes. Older Toyotas might be okay with short-term solutions. But newer cars need quick professional repairs to keep their value.

Never ignore safety warning signs. If your temperature gauge shows overheating, stop right away. Driving with a bad head gasket can ruin your engine.

Plan your next steps while using temporary fixes. Look for repair shops, get quotes, and save money. Temporary solutions give you time, but they don’t fix the problem for good.

Complete Cost Breakdown for Toyota Head Gasket Repairs

Fixing a Toyota head gasket is more than just replacing parts. It also includes labor and extra components. Knowing the Toyota head gasket repair cost helps you budget and avoid surprises.

Head gasket repairs are among the priciest engine jobs. They need a lot of work and time because of their complexity.

Labor Costs and Time Estimates

Head gasket labor costs are usually the biggest part of the bill. Replacing a Toyota head gasket takes 12 to 20 hours, depending on your car’s model and engine.

Technicians charge $100 to $150 an hour. So, labor alone can cost between $1,200 and $3,000, before adding parts and extra services.

Removing engine parts is a big job. Technicians have to take out the intake manifold, exhaust parts, timing components, and cylinder head. Each step needs care to avoid damage.

More labor may be needed if other problems are found. Issues like warped cylinder heads or damaged valves can add to the time and cost.

Parts and Materials Pricing

Parts for Toyota head gasket repairs cost more than just the gasket. A full repair needs many parts for a lasting fix.

The head gasket set costs between $150 and $400, based on your Toyota model. But, the repair also includes other essential parts that increase the total cost.

| Component | Price Range | Purpose | Replacement Frequency |

|---|---|---|---|

| Head Gasket Set | $150 – $400 | Primary seal replacement | Always replaced |

| Cylinder Head Bolts | $80 – $200 | Proper torque specifications | Usually replaced |

| Timing Belt/Chain | $100 – $300 | Prevent future failures | Often replaced |

| Coolant and Fluids | $50 – $150 | System refill and flush | Always replaced |

| Additional Seals | $75 – $200 | Complete seal renewal | Commonly replaced |

Choosing quality parts is key for a reliable fix. Toyota repair pricing often reflects the use of OEM or high-quality aftermarket parts. These parts last longer than cheaper alternatives.

Many repairs also need machine shop services for cylinder head inspection and resurfacing. These services add $200 to $500 to the total cost but ensure proper sealing surfaces.

Regional Price Variations

Where you live affects Toyota head gasket repair costs. Urban areas with higher labor rates charge more than rural areas. Parts availability also plays a role in pricing.

The West Coast and Northeast markets have the highest repair costs. Total expenses can range from $2,500 to $4,500 for a complete head gasket replacement. The Midwest and South offer more competitive pricing, with costs ranging from $1,800 to $3,500.

Dealership versus independent shop pricing is another big factor. Dealerships charge more but offer specialized expertise and warranty coverage. Independent shops can save you 20% to 30% while maintaining quality standards.

Parts availability in your area affects both cost and repair time. Remote areas may face higher parts costs due to shipping and limited competition.

The total Toyota head gasket repair cost usually ranges from $2,000 to $4,500 for most models. This includes labor, parts, fluids, and related services needed for a complete and reliable repair.

Getting quotes from different repair shops helps you understand local prices and find the best value. Remember, the cheapest option may not always be the best value in the long run.

Prevention Strategies to Avoid Future Head Gasket Problems

Preventing head gasket failure can save you a lot of money and keep your engine running longer. Regular maintenance and smart driving habits are key. Prevention is always cheaper than repair, and it’s true for major engine parts like head gaskets.

Most strategies to prevent head gasket problems focus on three main areas. These are keeping your cooling system in check, managing engine temperatures, and using top-notch coolant. Each part works together to shield your engine from issues that can lead to head gasket failure.

Maintenance Schedule for Your Cooling System

Keeping up with your cooling system’s maintenance is essential to avoid head gasket issues. Your Toyota’s cooling system needs regular care to stay in good shape. Here’s a simple schedule for most Toyota owners:

- Monthly checks: Check coolant levels and look for visible leaks

- Every 6 months: Check coolant color and consistency for contamination

- Annual service: Have cooling system pressure tested by a professional

- Every 2-3 years: Replace coolant according to manufacturer specifications

Regular maintenance catches small problems before they turn into big, costly repairs. Many Toyota owners overlook these simple checks, but they only take a few minutes.

Managing Engine Temperature Properly

Keeping your engine at the right temperature is key to protecting your head gasket from damage. Your temperature gauge is your best friend when it comes to engine health. Never ignore temperature warnings or unusual gauge readings.

Be on the lookout for temperature-related warning signs while driving. If your gauge goes above normal, pull over and turn off the engine right away. Driving with an overheating engine can easily damage your head gasket.

Fix cooling system issues as soon as you spot them. Small leaks can quickly turn into big problems if not fixed. Even minor overheating can weaken your head gasket over time.

Choosing and Replacing Quality Coolant

Choosing the right coolant is vital for keeping your head gasket in good shape. Your Toyota needs specific coolant types that meet the manufacturer’s standards. Using the wrong coolant can actually cause head gasket problems instead of preventing them.

Toyota recommends using their Long Life Coolant or similar products that meet their standards. These coolants have special additives that protect aluminum engine parts. Generic coolants may not offer the same level of protection.

Always follow the proper mixing ratio when adding coolant to your system. Most Toyota vehicles need a 50/50 mix of coolant and distilled water. Tap water can introduce minerals that harm your cooling system over time.

Replace your coolant as recommended by your owner’s manual, usually every 100,000 miles for long-life coolant. Fresh coolant keeps your head gasket healthy by maintaining proper pH levels and corrosion protection.

Navigating Insurance Claims and Warranty Coverage

Toyota head gasket problems can be costly. But, using warranty and insurance claims can help lower your expenses. Many Toyota owners don’t know they have other options than paying the full repair bill. Knowing your coverage and claim process can save you a lot of money.

Warranty coverage for head gasket repairs varies. It depends on your vehicle’s age, mileage, and protection type. Standard Toyota warranties usually don’t cover head gasket failures after the basic period ends. But, extended warranties and some insurance policies can help.

To succeed with claims, understand what’s covered and follow the right steps. Warranty providers and insurance companies have specific rules for major engine repairs.

Extended Warranty Claim Process

Filing extended warranty claims for head gasket repairs needs careful timing and steps. You must contact your warranty provider before starting any repair work to avoid denial. Most extended warranties require pre-authorization for major repairs like head gasket replacement.

First, review your warranty contract to know your coverage limits and exclusions. Extended warranties have different levels of coverage for engine parts. Some cover only parts, while others include both parts and labor costs.

Contact your warranty administrator as soon as you suspect head gasket problems. They’ll ask you to take your Toyota to an approved repair facility for diagnosis. The diagnostic process must be done by a certified technician for warranty acceptance.

After approval, your warranty provider will give you authorization for the repair. Keep all authorization numbers and correspondence for your records. The repair facility will usually bill your warranty company directly, but you might need to pay your deductible upfront.

Required Documentation and Evidence

Successful Toyota warranty head gasket claims need thorough documentation and evidence. Start gathering your paperwork as soon as you notice symptoms. Maintenance records are key to prove you’ve cared for your vehicle properly.

Essential documents for head gasket insurance coverage claims include:

- Complete maintenance history showing regular oil changes and cooling system service

- Original diagnostic reports from certified technicians

- Photos of visible symptoms like coolant leaks or contaminated oil

- Repair estimates from authorized Toyota service centers

- Your vehicle’s title and registration documents

Temperature logs can help your claim if you’ve been monitoring overheating issues. Document any warning lights, unusual noises, or performance changes with dates and mileage readings. This timeline shows when problems started and proves you acted quickly.

Professional diagnostic reports are very important. They should include compression test results, coolant system pressure tests, and chemical block test findings. Make sure all diagnostic work is done by certified technicians using proper equipment.

Keep copies of all communication with your warranty company or insurance provider. Regularly follow up on claim status and keep detailed records of all phone calls and emails. Persistence and organization often determine claim success with complex head gasket repair coverage.

Finding Qualified Toyota Service Providers

Finding the right Toyota head gasket repair service is key. You need technicians who are well-trained and dedicated to quality. Your choice affects the repair’s quality, cost, and how well your engine will run in the future. Both dealerships and independent shops have their own benefits and things to consider.

Choosing the right professionals is critical. They must know how to work on Toyota engines. Quality work is more important than the cheapest price. Bad repairs can cause more problems and cost more later on.

Authorized Dealership Advantages

Toyota dealership service centers offer many benefits. They have factory-trained technicians who keep up with the latest repair methods. They use genuine Toyota parts for the best fit and compatibility with your engine.

Dealerships often give warranties on repairs for a long time. These warranties cover parts and labor for up to a year or 12,000 miles. This gives you peace of mind and protects against future problems.

Dealerships have special equipment that connects to Toyota’s database. This lets technicians quickly find and fix known issues. They also follow the latest service bulletins and recalls.

Independent Shop Evaluation Criteria

A good Toyota specialist shop can offer great service at a good price. Look for shops that focus on Japanese cars or Toyota. ASE certification and Toyota training show they’re experts in engine repairs.

Ask about their experience with your Toyota model. Shops that work on Toyotas a lot often have good parts suppliers and know the latest fixes.

Get references from happy customers. A good shop will be proud to share contact info for satisfied customers. Also, check online reviews and the Better Business Bureau to see how customers feel.

Make sure the shop has insurance and offers a warranty on their work. Good shops stand behind their repairs with strong warranties.

| Service Provider Type | Typical Warranty Period | Parts Quality | Average Cost Range |

|---|---|---|---|

| Toyota Dealership | 12 months/12,000 miles | Genuine OEM parts | $2,500 – $4,000 |

| Certified Toyota Mechanic | 6-12 months/6,000-12,000 miles | OEM or high-quality aftermarket | $2,000 – $3,500 |

| General Auto Shop | 3-6 months/3,000-6,000 miles | Aftermarket parts | $1,500 – $2,800 |

| Independent Specialist | 6-12 months/6,000-12,000 miles | OEM or premium aftermarket | $1,800 – $3,200 |

Get detailed estimates before you decide. Look at labor costs, parts prices, and extra services. But remember, the cheapest price isn’t always the best deal.

Have a talk with the technician to understand their approach. A good professional will explain the repair clearly and answer your questions. This helps you make a smart choice for your Toyota’s repair.

Post-Repair Engine Care and Maintenance

Your Toyota’s head gasket repair is a big deal. Proper Toyota post-repair care is key to keeping your engine running well for years. The weeks after repair are vital for your engine’s health and avoiding future issues.

This time needs patience and careful attention. Your engine needs to adjust to its new setup. Following certain rules during this time protects your investment and boosts your Toyota’s reliability.

Initial Recovery Guidelines

The engine break-in period is 500 to 1,000 miles after repair. This lets your engine parts settle and seal right. Gentle driving habits are a must for the best results.

Drive at moderate speeds and avoid sudden acceleration. Try to keep highway speeds under 65 mph. Also, don’t tow or carry heavy loads during this time.

Watch your engine temperature closely in the first weeks. Stop right away if it overheats. Check coolant levels every day and look for leaks or fluid loss.

Ongoing Monitoring Procedures

Keep an eye on your engine over time. Regular visual inspections are part of your routine after repair. Look for coolant leaks, oil contamination, and exhaust smoke weekly.

Notice any changes in how your engine runs. Changes in idle, acceleration, or fuel economy can signal problems early.

Temperature checks are important even after the break-in period. Use a good engine temperature gauge if your Toyota doesn’t have one. Consistent temperature readings mean your cooling system is working right.

Keep a maintenance log. Record coolant levels, oil condition, and any odd symptoms. This info is useful for future service and warranty claims.

Modified Maintenance Requirements

Your head gasket maintenance schedule might change after repair. Oil changes will be more often in the first year. Change oil every 3,000 miles or three months, whichever comes first.

Coolant system care is more critical. Flush and replace coolant every 30,000 miles or two years. Use only Toyota-approved coolant to keep it protected.

Do cooling system checks more often. Have your radiator, hoses, and water pump checked every year. Preventive maintenance is cheaper than fixing head gasket problems again.

- Oil changes every 3,000 miles for the first year

- Coolant system inspection every 15,000 miles

- Thermostat replacement every 60,000 miles

- Radiator cap testing annually

Keep detailed maintenance records for warranty purposes. Many repair shops offer extended warranties on head gasket work. Proper documentation keeps your warranty valid.

Book follow-up appointments with your repair shop. Most shops suggest check-ups at 500, 1,000, and 5,000 miles after repair. These visits help catch issues early and give you peace of mind.

Consistent care and monitoring extend the life of your head gasket repair. Your effort during this critical time pays off in long-term engine reliability and performance.

Conclusion

Head gasket problems in Toyota vehicles are serious but not impossible to handle. Early detection is key. Look out for signs like white exhaust smoke, coolant loss, and overheating engines. Catching these early can save you a lot of money.

Regular maintenance is vital to avoid head gasket failures. Keep your Toyota’s coolant fresh, monitor its temperature, and schedule regular checks. Simple steps like checking coolant levels and watching your temperature gauge can prevent big issues.

If you do face head gasket problems, rely on professional Toyota service. Certified technicians have the right tools and know-how for fixing your car. While fixing a head gasket is expensive, getting it done right means your Toyota will run well again.

FAQ

What exactly is a head gasket and why is it so important in my Toyota?

A head gasket is a key seal between your Toyota’s engine block and cylinder head. It prevents coolant from getting into the combustion chambers and oil from mixing with coolant. It also keeps the engine’s compression right, which is vital for its performance.

This part faces extreme heat, pressure changes, and constant expansion and contraction. It’s one of the most stressed parts in your engine.

What are the most obvious warning signs that my Toyota’s head gasket is failing?

Look out for engine overheating, which you can see on your temperature gauge. Also, watch for coolant loss without any visible leaks. White exhaust smoke that’s not just condensation, milky or discolored oil, and coolant bubbles in the reservoir are other signs.

If you notice these symptoms, take action fast to avoid serious damage.

How can I tell the difference between normal exhaust condensation and head gasket failure?

Normal condensation is thin, wispy white vapor that goes away quickly, often on cold mornings. But head gasket failure makes thick, billowing white smoke that lasts even after the engine warms up. This smoke smells sweet from burning coolant.

If the white smoke keeps going for more than a few minutes after starting or during driving, it’s a serious issue.

What should I do if my Toyota starts overheating while driving?

Stop safely and turn off the engine right away. Never keep driving with an overheating engine, as it can damage the head gasket badly. Let the engine cool down completely before checking the coolant levels.

If the coolant is low, add some and have the car towed to a mechanic for a check-up. Don’t try to drive it.

Can I check for head gasket problems myself before going to a mechanic?

Yes, you can do some basic checks. Look at your coolant reservoir for the right levels and any color changes or oil contamination. Check your engine oil on the dipstick. Healthy oil should be amber to black, not milky or foamy.

Also, watch your exhaust smoke patterns during startup and normal driving. But these are just basic checks, and a professional test is needed for a sure diagnosis.

Which Toyota models are most prone to head gasket problems?

Some Toyota Camry models from 2007 to 2011 with 2.4L engines, certain Corolla models, and Toyota Prius hybrids have had more head gasket issues. But any Toyota can get head gasket problems due to overheating, age, or high mileage.

Regular maintenance and quick action on cooling system problems can help prevent issues, no matter the model.