Toyota Engine Vibration: Symptoms and Solutions

Ever felt your Toyota shaking at a red light? It’s not just annoying. It’s your car warning you of serious issues. Vehicle vibration problems can mean big mechanical troubles.

When your engine starts shaking, it’s not just a minor issue. Engine shaking often means there’s a bigger problem. If you ignore these signs, you could face expensive repairs later.

There are many reasons for these symptoms. Issues like fuel system problems, worn motor mounts, and ignition issues can cause it. Air flow and exhaust problems also play a part.

The good news is, catching these problems early can save you a lot of trouble. Knowing what causes them lets you act fast. This way, small issues don’t turn into big, costly repairs.

Key Takeaways

- Motor trembling indicates serious mechanical problems requiring prompt attention

- Multiple causes include fuel system issues, worn mounts, and ignition problems

- Ignoring symptoms leads to more expensive repairs and safety concerns

- Early diagnosis prevents minor issues from becoming major mechanical failures

- Regular maintenance is key to avoiding most motor problems

- Professional inspection quickly finds the root cause

Understanding Engine Vibration in Toyota Vehicles

Every Toyota engine vibrates as part of its normal engine operation. But, knowing when these vibrations mean trouble can save you money. It’s important to understand what causes these vibrations and when they’re a problem.

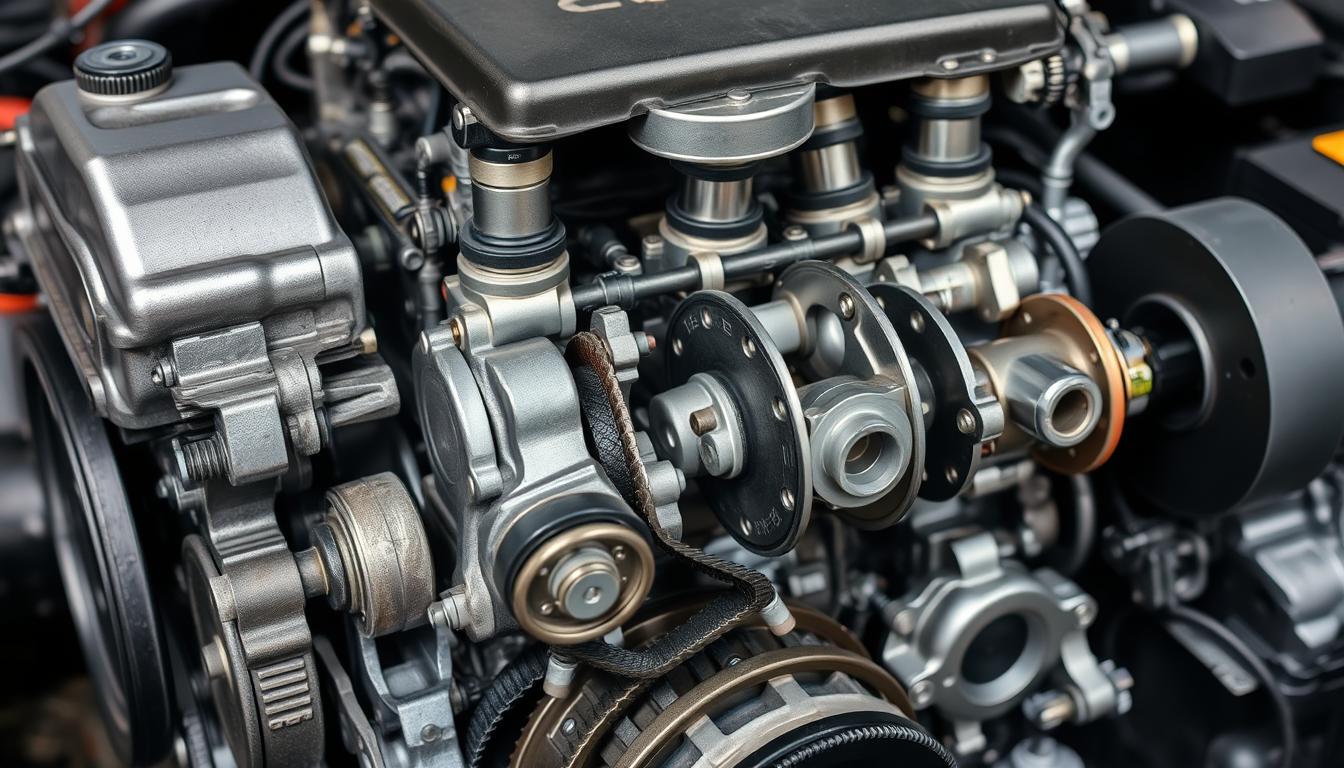

What Causes Engine Vibration

Many things cause engine vibration causes in your Toyota. The main reason is the explosions in engine cylinders. These explosions make power and move the engine.

The engine’s parts also add to the vibration. The crankshaft spins fast, and pistons move up and down quickly. Connecting rods help move this motion through the engine block.

Other parts like the transmission and engine accessories also vibrate. Even the cooling fan adds to the vibration.

Normal vs. Abnormal Vibration Levels

Toyota engineers make engines to have less vibration. They use proper balancing and mounting systems. Normal vibrations should feel smooth and steady. You might feel a little movement at idle, but it shouldn’t be harsh.

But, abnormal vibrations are different. They’re rough, not steady, or too strong. These vibrations might get worse when you speed up or slow down.

Impact on Vehicle Performance

When vibrations are too much, they can hurt your car’s performance. Your fuel might go down, and your car might not accelerate well. It might feel slow or uneven.

Too much vibration also makes driving uncomfortable. You’ll feel more movement in the steering wheel, seats, and pedals. If not fixed, it can damage more engine parts and cost a lot to repair.

Recognizing Common Toyota Engine Vibration Symptoms

Different types of engine vibration symptoms give clues about your Toyota’s issues. Knowing these signs helps fix problems early, avoiding costly repairs. Each vibration tells a story about your car’s health.

Vibration During Idle

Idle vibration happens when your Toyota is stopped but the engine is on. You’ll feel a shaking that makes the car tremble. This often happens at traffic lights or when parked.

Worn engine mounts can’t handle normal engine movement, causing vibration. Bad spark plugs lead to uneven combustion, making the engine shake. Dirty fuel injectors also prevent proper fuel delivery, causing engine shaking at idle.

Vibration During Acceleration

Acceleration shaking is more noticeable when you press the gas pedal. The vibration gets stronger as you speed up, feeling like something is loose. This usually means drivetrain problems.

Damaged engine mounts let the engine move too much during acceleration. Misaligned suspension parts also cause vibrations that get worse with speed. Worn CV joints make clicking sounds and shaking.

Steering Wheel and Dashboard Shaking

Vibrations through the steering wheel usually mean wheel or brake issues, not engine problems. But dashboard shaking often comes from engine or transmission issues. The vibration’s location helps find the problem.

Dashboard vibrations usually mean engine mount failure or internal engine problems. Seat vibrations suggest transmission or drivetrain issues. Brake pedal vibrations indicate warped rotors or brake system problems that need quick fixing.

Identifying When Engine Vibration Occurs

The timing of engine vibration gives clues about what’s wrong with your Toyota. Different problems cause vibrations at specific times while driving. By noticing when these vibrations happen, you can find the cause faster and save on repairs.

Knowing when the vibration occurs helps you talk better with mechanics. When you tell them exactly when the problem happens, they can fix it quicker.

At Startup and Warm-Up

Startup vibration that goes away as the engine warms up usually means cold-start system problems. Your Toyota might shake a lot at first, then get smoother as it warms up. This often means issues with the idle air control valve or engine timing.

But, persistent startup vibration that keeps going even after it warms up is a bigger problem. Worn engine mounts or internal engine issues usually cause this. These problems need quick attention to avoid more damage.

While Driving at Different Speeds

Speed-related vibration shows specific problems. Vibrations that only happen at certain speeds usually mean wheel or tire issues. If your Toyota shakes at 50-60 mph but not at other speeds, it’s likely unbalanced wheels.

Vibrations that get worse with speed often mean driveshaft or CV joint problems. These parts wear out and cause more shaking at higher speeds.

During Braking and Stopping

Braking vibration usually means brake system problems that need quick fixing for safety. If your steering wheel or brake pedal shakes when you stop, it’s likely warped brake rotors. This makes the shaking worse with harder braking.

Fix braking vibration fast because it affects how well your car stops. Ignoring it can lead to more costly repairs later.

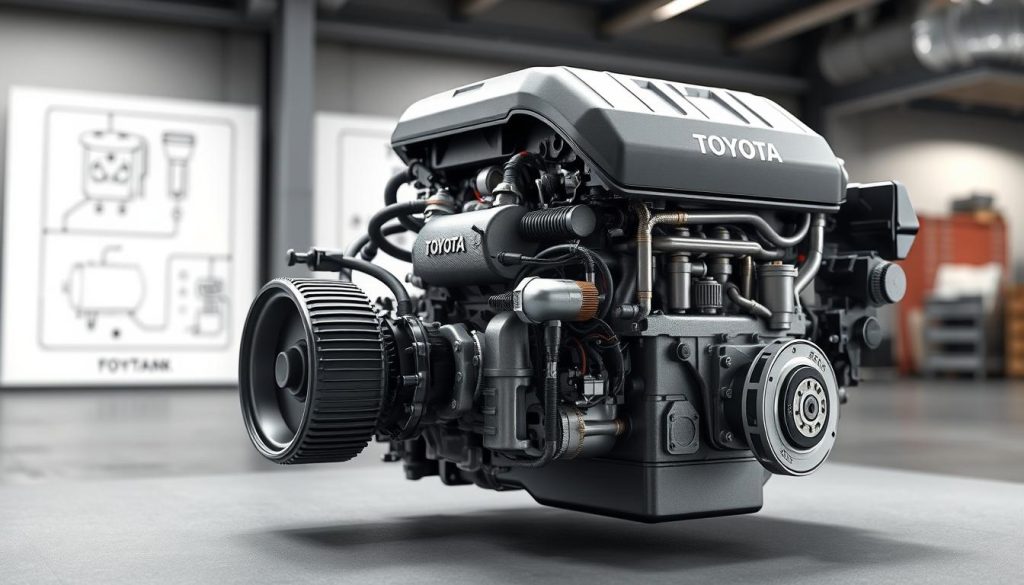

Diagnosing Engine Mount Problems

Your Toyota’s engine mounts connect the engine to the chassis. They absorb vibrations that could shake the whole car. Engine mount problems can cause shaking when idling, accelerating, or even when parked. It’s important to catch these issues early to avoid damage to your car’s drivetrain.

Most Toyotas have three to four engine mounts in the engine bay. These mounts use rubber or hydraulic materials that wear out over time. Heat, oil, and normal use can cause them to deteriorate.

Visual Inspection Techniques

Engine mount inspection starts with a close look at each mount. Open the hood and find the mounts. They look like metal brackets with rubber or fluid in the middle, connecting the engine to the frame.

Check for damage like cracked rubber, metal corrosion, or fluid leaks. Sagging or misaligned mounts show internal failure, even if they look fine on the outside.

Testing Mount Integrity

The best test is to have someone rev the engine while you watch. If the engine rocks or lifts too much, the mounts are worn out.

Try a brake test by applying the parking brake, shifting into drive, and pressing the accelerator gently. Abnormal vibration or clunking sounds mean the mounts are failing.

Professional Mount Replacement

While you can inspect mounts yourself, mount replacement needs a pro. This is because you need to support the engine during the swap. Shops usually suggest replacing mounts in pairs to keep the engine balanced.

Replacement costs depend on your Toyota model. But fixing engine mount problems quickly stops damage to other parts. This includes the exhaust system, radiator hoses, and electrical connections that can be harmed by too much engine movement.

Fixing Spark Plug and Ignition System Issues

Spark plug problems and ignition system malfunctions can turn your Toyota into a vibrating machine. These parts work together to make the precise combustion needed for smooth engine operation. When they fail, you’ll see rough idling, poor acceleration, and engine vibration.

Identifying Faulty Spark Plugs

Bad spark plugs show up through clear symptoms. Your Toyota might idle roughly, even when stopped at traffic lights. Engine misfire is noticeable during acceleration, causing jerky movement and vibration.

Look at your OBD2 scanner for misfire codes like P0300-P0308. These codes show which cylinder is having trouble. You can also check by removing spark plugs and looking for worn electrodes, carbon buildup, or oil fouling.

Replacing Spark Plugs Step-by-Step

First, get the right tools: socket wrench set, spark plug socket, and gap gauge. Always work on a cool engine for safety.

- Remove the engine cover and find spark plug wires or coil packs

- Carefully disconnect one spark plug wire at a time

- Use the spark plug socket to remove the old plug

- Check the gap on your new plug using manufacturer specs

- Install the new plug hand-tight, then tighten with the socket wrench

Solving Ignition Coil Problems

Ignition coils make the electrical signals needed for spark. When coils fail, symptoms are similar to bad spark plugs. Ignition system repair often means swapping coils between cylinders to find the bad one.

Replace failing coils with OEM or high-quality aftermarket parts. This stops future engine misfire issues and fixes vibration problems caused by uneven combustion.

Resolving Fuel System Related Vibration

Your Toyota’s fuel system is key for smooth engine running. Fuel system problems can disrupt this, causing engine vibrations. These issues often show up when idling or accelerating.

The fuel system must keep the fuel-air mix just right for best performance. Any trouble with fuel flow, pressure, or cleanliness leads to engine shakes and vibrations.

Cleaning Dirty Fuel Injectors

Dirty fuel injectors often cause Toyota engine vibrations. Clogged injectors mess up fuel spray, leading to uneven burning and engine roughness.

To clean injectors, use fuel system additives or get professional help. Add fuel injector cleaner to your gas tank every 3,000 miles to prevent clogs. For tough clogs, ultrasonic cleaning by pros works better than DIY products.

Replacing Fuel Filter

A clogged fuel filter limits fuel flow to your engine. This leads to lean running, causing vibrations and poor performance.

Change your Toyota’s fuel filter as recommended, usually every 30,000 to 40,000 miles. The filter’s spot varies by model, but it’s often near the fuel line or inside the tank.

Troubleshooting Fuel Pump Issues

Fuel pump issues can cause fuel pressure problems, leading to engine shakes. A failing pump may also cause your engine to hesitate, stall, or idle roughly.

Check fuel pressure with a gauge on the fuel rail. Compare it to your Toyota’s specs. If pressure is too low or changes a lot, replace the pump.

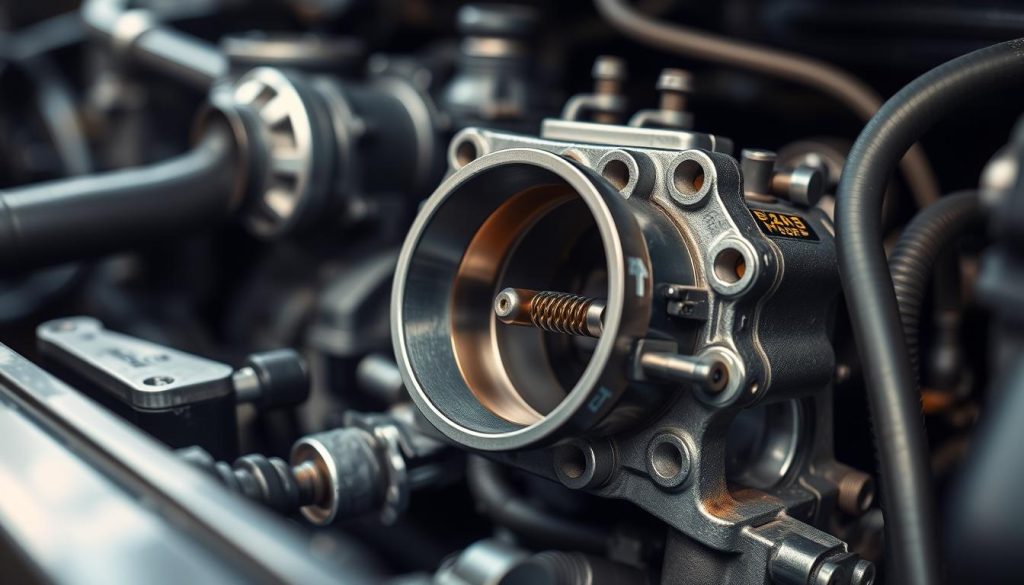

Cleaning Air Intake and Throttle Body Components

Your Toyota’s engine needs good airflow to run smoothly. Dirt and carbon buildup can block air intake components. This makes your engine struggle, leading to rough idling and vibrations.

A dirty throttle body or clogged air filter makes your engine work harder. Regular maintenance of these components prevents most airflow-related vibration problems. Vacuum leaks from loose hoses also disrupt the air-fuel mixture, causing erratic engine behavior.

Step-by-Step Cleaning Process

Begin your throttle body cleaning by disconnecting the negative battery cable for safety. Remove the air intake tube to access the throttle body assembly. Use carburetor cleaner and a soft cloth to remove carbon deposits from the throttle plate and bore.

Spray the cleaner generously but avoid getting it on electrical connections. Allow all components to dry completely before reassembly. This prevents damage to sensitive sensors during startup.

Filter Inspection and Replacement

Check your air filter every 12,000 miles or sooner in dusty conditions. A dirty filter appears gray or black instead of white or light colored. Air filter replacement takes just minutes but dramatically improves engine breathing.

Tap the old filter gently to remove loose dirt. If it remains heavily soiled, replace it immediately. Clean filters ensure optimal airflow and prevent contamination of downstream components.

Sensor Maintenance Guidelines

The mass airflow sensor measures incoming air precisely for proper fuel delivery. Clean this delicate component with specialized MAF cleaner spray only. Never use carburetor cleaner or touch the sensor wires directly.

Inspect vacuum hoses for cracks or loose connections during maintenance. Replace damaged hoses immediately to prevent vacuum leaks. Even small leaks can cause significant vibration problems.

| Component | Cleaning Frequency | Signs of Problems | Replacement Cost |

|---|---|---|---|

| Throttle Body | Every 30,000 miles | Rough idle, stalling | $15-25 (cleaning) |

| Air Filter | Every 12,000 miles | Reduced acceleration | $10-20 |

| Mass Airflow Sensor | Every 50,000 miles | Check engine light | $150-300 |

| Vacuum Hoses | As needed | Hissing sounds, rough idle | $5-15 per hose |

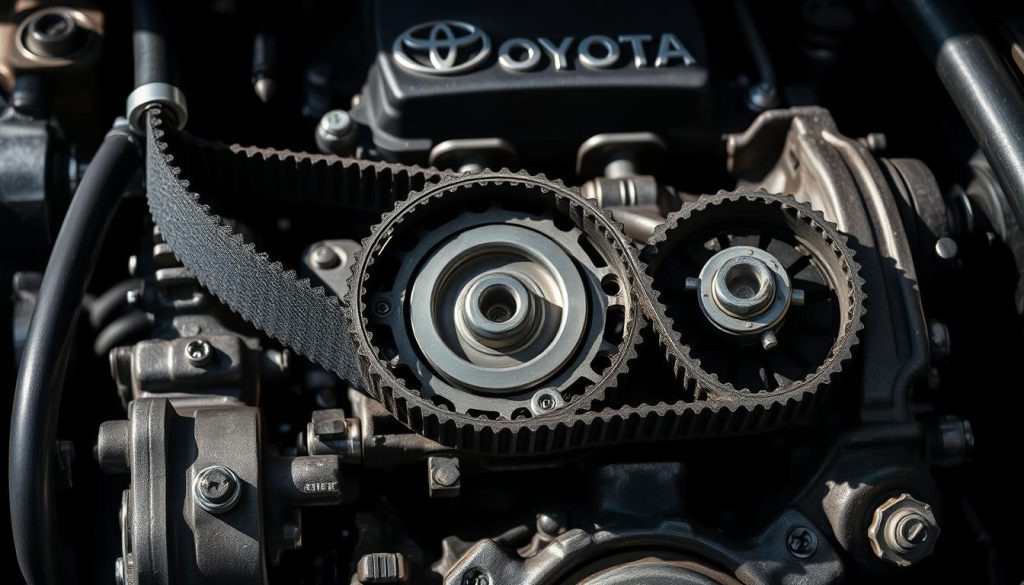

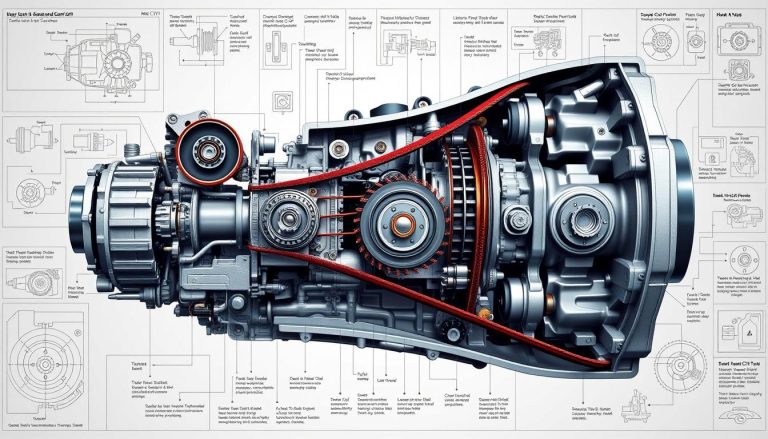

Addressing Timing Belt and Chain Issues

Toyota engines need precise timing to work right. Timing belt problems or timing chain issues can cause trouble. This includes vibrations, rough idling, and less power.

A bad timing part can make your engine shake or not start. It’s all about keeping the engine’s rhythm perfect.

Recognizing Warning Signs

Look out for signs of timing belt problems in your Toyota. Listen for rattling sounds when it’s cold. Your engine might idle roughly or shake more than usual.

Check the timing belt for cracks or fraying if you can see it. Timing chain issues make a rattling sound from the engine. Don’t ignore these signs to avoid expensive engine damage.

Replacement Schedule Guidelines

Toyota says when to replace timing parts. Most need a new timing belt between 60,000 and 100,000 miles. Engine timing parts wear out over time, so replacing them early is key.

Look in your owner’s manual for the exact timing. Cars with more miles need checks more often. Also, replace water pumps and tensioners at the same time to avoid more problems.

Professional Service Recommendations

Fixing timing systems needs special tools and skills. Professional technicians get it right. DIY fixes can lead to big problems or engine damage.

Go for certified Toyota techs who know your car. Modern timing systems are complex. It’s best to leave it to the pros.

| Toyota Model | Timing Component | Replacement Interval | Estimated Cost |

|---|---|---|---|

| Camry (4-cylinder) | Timing Chain | 100,000 miles | $800-$1,200 |

| Corolla | Timing Chain | 100,000 miles | $700-$1,000 |

| Highlander V6 | Timing Belt | 90,000 miles | $1,000-$1,500 |

| Sienna | Timing Belt | 90,000 miles | $1,200-$1,800 |

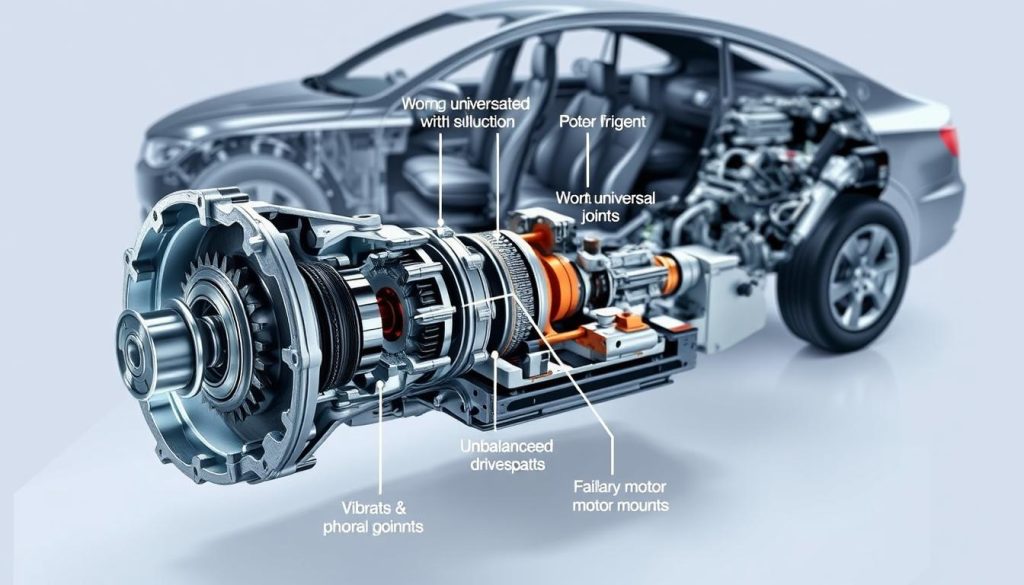

Fixing Transmission and Drivetrain Vibration

When your Toyota vibrates during acceleration or gear changes, it might not be the engine’s fault. The transmission and drivetrain are key in moving power to the wheels. Problems here can cause transmission vibration that feels like engine trouble. Knowing the difference helps you fix the right part and save money.

Diagnosing Automatic Transmission Issues

Automatic transmission problems show up as specific vibrations. Notice when the shaking happens during your drive. Vibrations during gear shifts mean the transmission is worn or low on fluid.

Check your transmission fluid regularly with the dipstick. If it’s dark or smells burnt, it’s overheated and damaged. Low fluid can cause rough shifting and vibrations in your Toyota.

Inspecting CV Joints and Axles

CV joint problems cause vibration when accelerating, mainly when turning. Listen for clicking sounds in sharp turns. This means the CV joints are worn and need fixing.

Look for tears or cracks in the CV joint boots. Damaged boots let dirt and moisture in, causing failure. CV joint problems get worse fast after contamination, so catch them early to save money.

Correcting Driveshaft Imbalance

A bent or unbalanced driveshaft causes strong vibrations that get worse with speed. These driveshaft issues often come from accidents or worn universal joints. The vibration is usually felt most in the floor or seat.

Fixing driveshaft problems needs special equipment. DIY attempts can be risky and won’t work. Trust qualified technicians for these complex repairs to keep your Toyota safe and running well.

Solving Wheel and Tire Related Vibration

Wheel and tire issues can seem like engine problems in Toyotas. These vibrations can travel through your car and feel like engine troubles. Knowing the difference can save you time and money on repairs.

Speed-related vibrations usually mean wheel or tire problems. If your Toyota shakes at high speeds but is smooth at idle, it’s likely a wheel or tire issue, not the engine.

Balancing and Alignment Solutions

Tire balancing fixes weight issues around your wheel and tire. Unbalanced tires vibrate at speeds between 50-70 mph.

Getting your tires balanced by a pro adds small weights. This is cheaper than fixing the engine and often stops vibrations.

Wheel alignment makes sure your tires hit the road right. Misaligned wheels cause uneven wear and vibrations. They also hurt fuel economy and tire life.

Damage and Wear Inspection

Look for these signs on your tires:

- Bulges or sidewall damage

- Uneven tread wear patterns

- Cuts or punctures

- Low tread depth

Bent wheels from potholes cause vibrations. These need a pro to fix or replace for smooth driving.

Bearing Diagnosis and Repair

Wheel bearing problems make grinding noises and vibrations that get worse with speed. Worn bearings let wheels move too much.

Test wheel bearings by lifting each wheel and checking for play. Too much movement means you need new bearings. Don’t wait to fix this – bad bearings can cause wheels to separate and lead to accidents.

Repairing Brake System Vibration Problems

Vibrations when you apply the brakes mean you have a serious problem. Unlike engine shakes, brake vibration only happens when you brake. It can be felt through the brake pedal, steering wheel, or the whole car. These issues are very dangerous because they make it hard for your Toyota to stop safely.

Identifying Warped Brake Rotors

Warped rotors are the main reason for brake vibrations in Toyotas. You’ll feel a pulsating brake pedal when stopping, even from high speeds. The steering wheel might shake, and stopping distances get longer.

Use a micrometer to check rotor thickness and a dial indicator for runout. Rotors that are too thick or have too much runout need to be replaced. Some rotors can be resurfaced if they’re thick enough, but badly warped ones must be replaced.

Brake Pad Inspection and Replacement

Worn brake pads cause vibrations and make braking less effective. Check pad thickness through the wheel spokes or remove the wheel for better access. Pads that are less than 3mm thick should be replaced right away.

Look for signs of uneven wear, glazing, or dirt on the pads. Brake pad replacement should include cleaning the caliper mounting points and applying brake grease. This prevents noise and ensures smooth operation.

Caliper Maintenance and Repair

Sticking brake calipers lead to uneven pad wear and vibrations. Clean and lubricate caliper slide pins often to avoid sticking. Also, check brake fluid levels and brake lines for leaks or damage.

Professional service is strongly recommended for complex brake repairs. While you can look at brake parts yourself, actual repairs need the right tools and knowledge for your safety.

Complete Step-by-Step Diagnostic Process

Toyota owners can find the cause of engine vibrations by following a detailed diagnostic process. This method avoids expensive mistakes and ensures you fix the real problem. Proper vibration diagnosis saves both time and money by focusing repairs on the right areas.

“The biggest mistake I see is people replacing parts without proper diagnosis first,” says automotive expert Mike Johnson. “A methodical approach catches problems that random part swapping misses completely.”

Visual Inspection Checklist

Begin by visually checking important parts. Look for cracks or movement in engine mounts when the engine is running. Also, check vacuum hoses for damage or loose connections that could cause a rough idle.

Check drive belts for signs of wear or improper tension. Make sure fluid levels are correct, as low levels can cause problems. Document everything you find to track patterns and connections between issues.

OBD2 Scanner Usage

An OBD2 scanner is key for finding diagnostic information. Connect it and get trouble codes that show system malfunctions. Look at freeze frame data to understand engine conditions when codes were set.

Clear codes after documenting them, then test drive to see if they come back. Multiple codes often point to a single root cause instead of separate issues.

Systematic Test Drive Protocol

Do controlled test drives to pinpoint when vibrations happen most. Test at idle, during acceleration, at steady speeds, and while braking. Note how vibrations affect the steering wheel, seats, or the whole vehicle.

Record how intense and frequent vibrations are at different RPMs. This method helps narrow down possible causes before replacing parts.

Effective DIY Solutions for Toyota Engine Vibration

Fixing engine vibration in your Toyota can be done without spending a lot. Many issues can be solved with DIY engine repair and regular upkeep. This way, you can save money and keep your car running well.

Preventive maintenance is key to avoiding vibrations. Simple tasks like oil changes every 5,000 miles and air filter replacements can stop many problems before they begin.

Essential Maintenance Steps

Begin with basic maintenance to prevent vibrations. Replace spark plugs every 60,000 to 100,000 miles, as your Toyota suggests. Also, clean or replace air filters every 12,000 to 15,000 miles for good airflow.

Cleaning the fuel system is also effective. Use a quality fuel system cleaner every 3,000 miles. Remember to check and replace fuel filters as your owner’s manual advises.

Don’t forget to inspect engine mounts during regular checks. Look for any signs of damage or loose bolts that could cause vibrations.

Required Tools and Equipment

You’ll need basic maintenance tools for most DIY repairs. A socket set, torque wrench, and OBD2 scanner are essential. Also, quality jack stands and wheel chocks are important for safe lifting.

For specific repairs, you might need spark plug sockets and fuel line disconnect tools. A multimeter is handy for checking electrical issues that might cause vibrations.

Important Safety Precautions

Always follow safety precautions when doing DIY engine repair. Never work under a car supported by a jack alone. Always use jack stands on level ground.

Make sure the engine is cool before working on the fuel system. Disconnect the battery when near electrical systems. Wear safety glasses and gloves when handling fluids or chemicals.

Know your limits and get professional help for complex repairs like timing systems or transmission work.

Knowing When to Seek Professional Assistance

Some engine vibration problems are too big for home repairs. They need special tools and expert knowledge. Simple maintenance can fix many issues, but complex ones need more than DIY skills.

Complex Engine and Transmission Problems

Internal engine damage and transmission issues need professional auto repair. These problems require tools that basic scanners can’t access.

Signs like vibration after fixing obvious parts or strange noises with vibration mean it’s complex. Also, vibrations during shifting or at certain RPMs need a pro’s touch.

Warranty and Insurance Considerations

DIY fixes can ruin your car’s warranty. Warranty considerations are key before you start. Only authorized dealers can do warranty work.

Keeping records of professional repairs is important. It helps with insurance claims and keeps your car’s value up. Insurance wants certified repair records to approve claims.

Finding Qualified Toyota Service Centers

Look for ASE-certified techs and Toyota service centers with experience. Check their certifications and what tools they use.

Building trust with service providers is important. Ask for detailed repair estimates and get a second opinion on big repairs. Good communication helps techs solve problems right.

Tell the tech about your symptoms. Explain when the vibrations happen, how strong they are, and any sounds or performance issues.

Taking Control of Your Toyota’s Performance

Engine vibration in your Toyota doesn’t have to be a big problem. With the knowledge from this guide, you can spot issues early and fix them. Knowing the cause, whether it’s worn engine mounts or faulty spark plugs, gives you control.

Successful Toyota engine maintenance starts with a good diagnosis. Begin with simple checks and then move to more complex repairs if needed. This method saves time and money and ensures you fix the real problem.

Ignoring engine shaking can lead to bigger issues. What seems like a small vibration can turn into costly damage to the transmission or engine. Fixing problems early saves your wallet.

Regular maintenance prevents vibration and keeps your Toyota running well. Change spark plugs on time, check engine mounts, and keep the fuel system clean. These steps help your vehicle stay reliable for years.

Your Toyota was made to last. With the right care and attention to vibration symptoms, you can enjoy reliable rides. Be proactive about your vehicle’s needs and trust your instincts. Taking action now avoids bigger problems later.

FAQ

What’s the difference between normal and abnormal engine vibration in Toyota vehicles?

Toyota engines naturally vibrate a bit. Normal vibrations are small and steady. But, if vibrations are strong or change, it’s a sign of trouble.

Feeling vibrations in the steering wheel or seats is a warning. It can also affect how well your car runs and feels.

How can I tell if my Toyota’s engine mounts are causing the vibration?

Look for cracks or leaks in the mounts. A “rev test” can show if mounts are worn. If the engine moves too much, it’s time to replace the mounts.

Mount problems are often noticed when the engine is idling. But, they might feel better when you rev the engine.

When should I replace my Toyota’s spark plugs to prevent vibration issues?

Spark plugs need replacing every 60,000 to 100,000 miles. Do it sooner if your car runs rough or doesn’t accelerate well.

Worn spark plugs can cause vibrations. They can also lead to bigger problems if not fixed.

Can dirty fuel injectors cause my Toyota engine to vibrate?

Yes, dirty fuel injectors can cause uneven fuel flow. This leads to a rough idle and vibrations. Look for poor idle, hesitation when accelerating, and more emissions.

Try a fuel system cleaner first. But, if injectors are really clogged, you might need a pro to clean or replace them.

How do I know if my Toyota’s timing belt is causing vibration problems?

Look for engine rattling, rough idle, and vibrations. Check your manual for when to replace the timing belt, usually between 60,000 to 100,000 miles.

Don’t wait for it to break. A broken timing belt can damage your engine badly. This job is best left to a pro.

Why does my Toyota vibrate only when I press the brakes?

Vibrations when braking usually mean warped brake rotors or worn pads. You’ll feel it in the brake pedal or steering wheel.

This is a serious safety issue. Get your brakes checked by a pro right away.

What tools do I need for basic Toyota engine vibration diagnosis?

You’ll need an OBD2 scanner, socket sets, a torque wrench, and a flashlight. Safety gear like jack stands is also key.

For tougher problems, you might need special tools. These are best left to the pros, like for timing or transmission issues.

Can tire problems cause vibrations that feel like engine issues?

Yes, bad tires or wheels can make your car vibrate. This is more noticeable at higher speeds. It can also shake the steering wheel.

Getting your tires balanced and wheels aligned can fix this. A pro can do this for you.

How often should I clean my Toyota’s throttle body to prevent vibration?

Clean your throttle body every 30,000 to 50,000 miles or if your car runs poorly. A dirty throttle body can cause vibrations.

This is a simple task you can do yourself. It helps keep your engine running smoothly.

When should I seek professional help instead of trying DIY repairs?

Get a pro for complex issues like timing systems, transmission problems, or engine troubles. Also, if you’re not sure about a repair or lack the right tools.

Warranty and insurance rules might also require a pro. Safety is always a top priority.

What’s the most cost-effective approach to fixing Toyota engine vibration?

Start with simple maintenance like spark plug changes and throttle body cleaning. Use a systematic approach to find the problem.

Fixing issues early saves money. Regular maintenance can prevent many vibration problems.

How do I differentiate between transmission and engine vibration in my Toyota?

Engine vibrations are usually felt at idle and get better with RPM. Transmission vibrations happen during gear changes or at specific speeds.

Pay attention to when vibrations occur. This helps you know if it’s the engine or transmission.