Why Is My Toyota Making Engine Noise? Find Out

Hearing unusual sounds from under your hood can be alarming. Whether it’s a subtle tick or a loud knock, these car engine sounds often signal that your vehicle needs attention. Don’t ignore these warning signs – they’re your car’s way of communicating possible problems.

The range of automotive issues causing these sounds varies widely. Some problems stem from simple maintenance needs like low oil levels or worn belts. Others indicate more serious mechanical concerns that require immediate professional automotive troubleshooting. Early detection and proper diagnosis can save you hundreds or even thousands of dollars in repair costs.

Toyota vehicles are known for their exceptional reliability and longevity. Yet, even the most dependable cars develop issues over time. The good news is that most Toyota engine noise problems can be identified and resolved with the right approach. This guide will help you understand what those sounds mean and when to seek professional help.

Key Takeaways

- Unusual car sounds often indicate maintenance needs or mechanical problems

- Early diagnosis prevents costly repairs and possible engine damage

- Toyota’s reliability doesn’t eliminate the need for regular attention to warning signs

- Most engine noise issues can be identified and resolved with proper knowledge

- Professional automotive troubleshooting may be necessary for complex problems

Understanding Different Types of Engine Sounds in Your Toyota

Learning to understand your Toyota’s engine sounds makes you a more informed car owner. You can spot issues before they cost a lot to fix. Every Toyota engine has its own sound during operation. Knowing this helps you keep your car in top shape.

Your engine makes many sounds, but most are normal and mean everything is working well. But, some sounds mean you need to check things right away.

Normal Operating Sounds vs. Problematic Noises

Normal engine noise includes sounds you should know. The hum of the engine when it’s idle is one. You’ll also hear the cooling fan turn on and off.

Light clicking sounds at idle are normal in many Toyotas. This is because hydraulic lifters adjust to keep valves right. Fuel injectors also make clicking sounds as they work.

Belt-driven accessories make their own sounds. The alternator, power steering pump, and air conditioning compressor all make quiet noises. These sounds should stay consistent and not be too loud.

Problematic car sounds are different. They’re loud, new, or irregular. Knocking sounds during acceleration mean something might be wrong inside. Grinding noises mean metal is touching metal and need fixing fast.

Squealing sounds usually mean belt or bearing problems. Rattling noises can mean loose parts or worn engine mounts. If a sound seems off, it’s worth checking.

How Engine Noise Patterns Indicate Specific Issues

The timing of engine sounds is very important. Startup noises often tell you about oil or cold engine parts. These sounds usually go away after a few minutes.

Noises when you accelerate point to different issues than when the engine is just idling. Knocking sounds during acceleration might mean fuel quality or carbon buildup. Grinding sounds during acceleration could mean transmission or drivetrain problems.

Idling noises often point to engine parts. Ticking sounds that match engine RPM usually mean valve train issues. Knocking sounds that get worse under load often mean bearing problems.

Some sounds change with temperature. Cold engine noises that go away when warm are usually normal. Sounds that only happen when it’s hot might mean overheating issues.

Writing down when you hear certain sounds helps mechanics fix problems faster. Note if sounds happen during startup, idle, acceleration, or deceleration. This saves time and money on repairs.

Common Causes Behind Toyota Engine Noise

Knowing why your Toyota engine makes noise is key to avoiding expensive fixes. Most engine sounds hint at specific problems. Spotting these issues early can save your engine from serious damage.

Your engine oil’s condition greatly affects noise levels. Low or dirty oil means parts rub together, making noise. This is because they lack the lubrication they need.

Timing belt and chain issues are common noise culprits. These parts keep the engine running smoothly. When they wear out, they make sounds that need quick attention.

“Regular Toyota maintenance prevents 80% of engine noise issues before they start,” according to automotive service data.

Knocking and Pinging Sounds

Engine knocking happens when fuel burns too soon. This makes a sharp, metallic sound. It’s often due to carbon buildup on pistons and cylinder heads.

Using the wrong fuel octane can also cause knocking. Lower octane fuel burns too easily, leading to pinging sounds, mainly when you accelerate.

Worn-out parts like rod bearings or main bearings can knock too. These parts support the engine’s moving parts. When they wear out, they make loud knocking sounds that get worse with speed.

Grinding and Scraping Noises

Grinding noise means metal is rubbing against metal. A failing water pump is a common cause. Its bearings wear out, causing grinding sounds.

Timing chain issues also lead to grinding or scraping sounds, often at startup. Stretched chains rattle against guides and tensioners. Worn guides let the chain move too much, causing grinding.

Damaged exhaust system parts can also make grinding sounds. Loose heat shields or broken exhaust manifolds create scraping noises that get louder with engine RPM changes.

Squealing and Whistling Sounds

Squealing belts make high-pitched sounds, often at startup or when you accelerate. Worn belts slip on pulleys, making squealing noises. Loose belt tension or glazed belt surfaces are common causes.

Vacuum leaks cause whistling sounds as air enters the engine. These leaks disrupt air-fuel mixture ratios. The whistling gets louder with engine RPM and affects idle quality.

Failing pulleys and tensioners also squeal. Worn pulley bearings make high-pitched noises during engine operation. Bad tensioners let belts slip and squeal on pulley surfaces.

Step 1: Determine When Your Toyota Engine Noise Occurs

To solve Toyota engine noise problems, it’s important to track when these sounds happen. Timing is everything for accurate diagnosis. Different noises at specific times show different mechanical issues that need specific fixes.

Environmental factors like cold weather or hot conditions can change how engine noises sound. Temperature, humidity, and even altitude affect your Toyota’s engine performance and sounds.

Keeping a systematic record of noise helps both DIY fans and pros. This methodical way cuts down on guesswork and leads to quicker, more precise repairs.

Documenting Noise During Startup

Engine startup noise gives clues about your Toyota’s health. Cold start conditions are key because oil hasn’t circulated fully yet. Listen for sounds in the first 30 seconds of starting.

Common startup sounds include a timing chain rattle, like marbles in a can. Oil circulation problems make ticking or tapping sounds. Worn starter parts make grinding or whirring noises before the engine starts.

See if the noise goes away as the engine warms up. Temporary startup sounds often mean different problems than constant noises. Note the outside temperature when these sounds happen, as cold weather makes many startup issues worse.

Identifying Acceleration-Related Sounds

Acceleration sounds show problems with fuel, timing, and power systems. Engine knock during acceleration usually means fuel quality or timing issues. This metallic pinging gets louder under load.

Transmission sounds during acceleration are different from engine noises but often get mixed up. Whining during acceleration might mean transmission trouble, not engine issues. Exhaust system problems also show up more when accelerating.

Try your Toyota at different speeds. Gentle starts might not trigger sounds that show up when you accelerate hard. Note the RPM range where noises are loudest.

Noting Idle and Low RPM Noises

Idle engine problems show up as steady, rhythmic sounds when the car is stopped. Valve train issues are most clear at idle because there’s less background noise. Carbon buildup causes irregular idle patterns and sounds.

Engine mount problems cause vibrations that sound like noise at idle. These sounds might go away when you shift into neutral or park. Vacuum leaks make hissing sounds most noticeable at low RPMs.

Watch your Toyota’s idle quality in different situations. Using air conditioning, power steering, and electrical loads can change idle sounds and characteristics.

| Noise Timing | Common Sounds | Likely Causes | Documentation Notes |

|---|---|---|---|

| Cold Startup | Ticking, rattling, grinding | Oil circulation, timing chain, starter | Record duration and temperature |

| Acceleration | Knocking, pinging, whining | Fuel quality, timing, transmission | Note RPM range and load conditions |

| Idle/Low RPM | Tapping, hissing, irregular rhythm | Valve train, vacuum leaks, mounts | Check with accessories on/off |

| Warm Engine | Persistent knocking, squealing | Internal wear, belt problems | Compare to cold start sounds |

Consistent documentation gives a clear picture of your Toyota’s state. Use your smartphone to record audio when it’s safe. Video recordings can capture sound and visual clues like smoke or vibrations.

Share this info with your technician if you need help. Detailed observations help technicians find the problem faster, saving time and money.

Step 2: Locate the Source of the Engine Noise

After noting when the noise happens, finding where it comes from in your engine bay is key. Effective engine noise diagnosis requires patience and systematic investigation to find the exact source. You can use simple tools and methods at home.

Combining listening with looking is the best way to solve this. Check each area one by one to avoid mistakes.

Using Basic Listening Tools

An automotive stethoscope is your main tool for finding engine sounds. It makes noises clearer, helping you spot problems. Professional mechanics use these tools because they’re accurate.

If you don’t have a stethoscope, a long screwdriver works too. Hold it against engine parts and listen with the handle. It’s a simple way to hear engine noises.

Smartphone apps can also help by recording and analyzing sounds. They catch noises that might be hard to hear when you’re listening.

Performing Visual Inspection

Visual inspection is very helpful when combined with listening. Look at your engine bay while it’s running but stay away from moving parts. Look for signs of wear, damage, or loose parts.

Focus on where the noise is loudest. Look for oil leaks, frayed belts, or corroded connections. Fresh oil stains or metal shavings often mean a part is failing.

Watch for parts that vibrate or move when they shouldn’t. These parts need attention right away.

Checking Engine Bay Components

Checking the engine bay involves looking at parts from top to bottom and front to back. Start with easy-to-reach parts like the air filter housing. Then move to more complex areas. This way, you make sure you don’t miss anything.

Here’s what to check:

- Valve cover and cylinder head area for ticking or tapping sounds

- Timing belt or chain cover for rattling noises

- Alternator, power steering pump, and other accessories for squealing

- Oil pan and lower engine block for knocking sounds

Turn off your engine to cool parts during inspection. Hot engine parts can cause serious burns, so safety first. Take notes to help with your diagnosis.

Step 3: Check Oil Level and Quality

Engine oil is vital for your Toyota’s motor. Its condition affects noise levels. Low or contaminated oil causes friction between parts, leading to sounds like ticking or grinding. An engine oil check is your next step after finding the noise’s source.

Most Toyota engine noises come from oil problems. Fresh oil keeps parts moving smoothly and quietly. But old or not enough oil lets parts rub together, making sounds.

Inspecting Oil Dipstick

Checking the oil dipstick needs the right timing and method. Wait at least five minutes after turning off your engine before checking the oil level. This lets the oil settle for an accurate reading.

Here’s how to inspect the dipstick correctly:

- Remove the dipstick completely and clean it with a lint-free cloth

- Insert the dipstick fully back into its tube until it seats properly

- Pull it out immediately and check the oil level against the minimum and maximum marks

- Look for oil film on both sides of the dipstick for the most accurate reading

The oil level should be between the minimum and maximum marks. Oil below the minimum line can cause serious engine damage and noise issues.

Evaluating Oil Color and Consistency

Checking oil quality means looking at color and texture. Fresh oil is amber or honey-colored and flows smoothly. Dirty oil turns darker, becoming black or showing particles.

Here are oil quality signs to watch:

- Color: Amber to light brown is good; black means it’s time to replace

- Consistency: Oil should flow easily; thick, gummy texture means contamination

- Debris: Metal particles or sludge indicate internal engine wear

- Smell: Burnt odor suggests overheating or extended service intervals

Contaminated oil doesn’t lubricate well. This leads to increased friction and engine noises.

Testing Oil Pressure

Oil pressure problems can cause engine noise before dashboard lights turn on. Professional oil pressure test equipment provides the most accurate readings, but you can spot issues through symptoms.

Look out for these low oil pressure signs:

- Ticking or tapping sounds that increase with engine RPM

- Oil pressure warning light activation during operation

- Grinding noises from the upper engine area

- Rattling sounds during acceleration

Low oil pressure means parts don’t get enough lubrication. This condition produces the metallic sounds you’re experiencing. If you suspect pressure issues, stop driving and get a qualified technician’s help.

Diagnosing Timing Chain and Belt Problems

The timing chain and serpentine belt in your Toyota make unique sounds when they wear out. These parts work together to keep your engine running smoothly. When they fail, they make noises that help you spot the problem early.

Over time, timing belts and chains can stretch or wear out completely. This causes irregular operation and loud grinding or clicking sounds. If the timing chain becomes loose, you’ll hear specific rattling noises as the engine operates.

Recognizing Timing Chain Rattle

Timing chain noise sounds like a metallic rattling or grinding from the front of your engine. This sound is most noticeable during startup when the engine is cold. You might also hear it at idle or when the engine is under light load.

The rattling occurs when the timing chain stretches beyond its normal limits. Worn chain tensioners can’t maintain proper tension anymore. This allows the chain to slap against the timing cover or guides.

Listen carefully during the first few seconds after starting your Toyota. A healthy timing chain should run quietly. If you hear persistent rattling that doesn’t go away after warmup, your timing chain may need attention.

Identifying Serpentine Belt Issues

Serpentine belt problems create different sounds than timing chain issues. You’ll typically hear squealing, chirping, or slapping noises that change with engine speed. These sounds often become louder when you turn on accessories like air conditioning or power steering.

Visual inspection reveals important clues about belt condition. Look for these warning signs:

- Cracks running across the belt’s surface

- Fraying or splitting along the edges

- Glazing that makes the belt appear shiny

- Missing chunks or pieces of rubber

Check belt tension using the deflection method. Press down on the belt midway between pulleys. It should deflect about half an inch with moderate pressure. Too much deflection indicates a loose belt that needs adjustment.

Checking Tensioner and Pulley Condition

Belt tensioner issues often cause intermittent squealing or grinding sounds. Automatic tensioners that fail can’t maintain proper belt tension. This leads to belt slippage and premature wear.

Perform pulley inspection by listening to each pulley individually. Worn bearings create grinding or whirring sounds that become more noticeable as the engine warms up. You can often isolate the problem by using a long screwdriver or stethoscope to listen to each pulley.

Watch for tensioner arm movement while the engine runs. The tensioner should remain relatively steady. Excessive bouncing or vibration indicates internal spring or hydraulic failure.

Remember that timing component failure can cause serious engine damage. If you hear persistent rattling from the timing chain or notice severe belt tensioner issues, seek professional help immediately. These problems rarely fix themselves and typically worsen over time.

Identifying Valve Train Noise Issues

Toyota owners can spot valve train problems early by listening to engine sounds. The system includes lifters, rocker arms, and valves. These parts work together to control how the engine breathes. When they wear out, they make specific noises that show their condition.

Diagnosing valve train issues early can save your engine from damage. These parts work under high pressure and heat. Catching problems early stops engine failure.

Valve Lifter Ticking Diagnosis

Valve lifter noise sounds like quick clicking or tapping inside your engine. It’s most noticeable when your Toyota starts cold after sitting overnight. The sound usually goes away as the engine warms up.

Hydraulic lifters need oil pressure to keep the right valve clearance. Low or dirty oil makes them collapse partially. This causes the ticking sound many Toyota owners know.

Look out for these signs of lifter trouble:

- Rapid ticking that matches engine RPM

- Noise that’s loudest during cold starts

- Sound that comes from the top of the engine

- Ticking that may fade after warm-up

Rocker Arm Problem Detection

Rocker arm problems make a heavier ticking or knocking sound. This indicates worn rocker arms or damaged mounting points. The sound stays the same, no matter the engine temperature.

Rocker arms move the motion from camshafts to valves. Worn or damaged parts make a metallic knocking sound. This sound is deeper and louder than lifter noise.

Signs of rocker arm trouble include:

- Heavy knocking from the cylinder head

- Noise that doesn’t improve with warm-up

- Metallic sounds during acceleration

- Consistent ticking at all RPM levels

Valve Clearance Assessment

Valve clearance problems make a metallic tapping sound that gets louder with RPM. Too much clearance causes valves to slam against their seats. Too little clearance stops valves from closing fully.

Toyota engines with adjustable valves need clearance checks. Too much clearance makes loud tapping noises. Too little causes valve burning and power loss. Both harm your engine over time.

Right valve clearance keeps your engine running well and lasts longer. Regular checks prevent expensive repairs.

Signs of valve clearance trouble include:

- Metallic tapping that increases with RPM

- Loss of engine power during acceleration

- Rough idle or misfiring

- Unusual exhaust smoke or backfiring

Regular oil changes prevent many valve train problems. Clean oil keeps hydraulic lifters working right. Quality oil also lubricates rocker arms and reduces wear on valve parts.

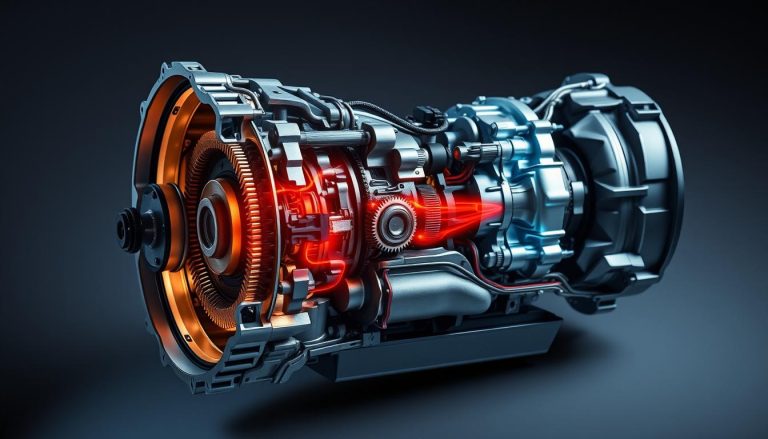

Recognizing Serious Internal Engine Problems

Your Toyota’s engine troubles show up with specific sounds. These internal engine problems make noises that are different from minor issues. Hearing these sounds means you need to act fast to avoid engine failure.

Internal engine damage hits the heart of your engine. The sounds are deep, metallic, and rhythmic. They get worse when you load the engine and might go away when it cools down.

Heavy Knocking from Rod Bearings

Rod bearing knock is a loud and scary sound your Toyota can make. It gets louder with engine RPM and is more noticeable when you accelerate. This sound comes from worn bearings that let the connecting rod and crankshaft move too much.

This rod bearing knock sounds like a deep, metallic hammering from the middle or lower part of your engine. It often comes with low oil pressure warnings on your dashboard. Each engine revolution makes a distinct knock as the damaged bearing lets metal touch metal.

Driving with rod bearing knock can lead to engine failure in miles or minutes. The damaged bearing can seize, causing the connecting rod to break through the engine block. This failure means you’ll need a new engine or a complete rebuild.

Deep Rumbling from Main Bearings

Main bearing failure makes a deep, rumbling knock from the bottom of your engine. This sound is different from rod bearing knock because it’s lower and more continuous. You might feel vibrations through the steering wheel or floorboard along with the noise.

Main bearing problems start as a subtle rumble during startup and get worse over time. The sound might quiet down when you rev the engine but comes back when RPMs drop. Oil pressure usually drops a lot when main bearings start to fail.

This main bearing failure needs quick professional help. Main bearings support the crankshaft, and their failure can destroy the engine block. Don’t drive far if you think you have main bearing problems.

Hollow Sounds from Piston Issues

Piston damage makes different sounds depending on the problem. Piston slap sounds like a hollow, knocking noise, most noticeable when the engine is cold. This happens when pistons have too much clearance in their cylinders, causing them to rock back and forth.

Ring flutter sounds like rapid chattering, mainly during acceleration. Damaged piston rings let combustion gases escape, reducing engine power and making unusual noises. You might also see more oil consumption and blue smoke from the exhaust.

Scored cylinders or cracked pistons produce grinding or scraping sounds that get worse with engine load. These problems often come from overheating, poor lubrication, or foreign objects in the combustion chamber. Fixing these issues usually means taking the engine apart.

| Problem Type | Sound Characteristics | When Most Noticeable | Urgency Level |

|---|---|---|---|

| Rod Bearing Knock | Heavy, rhythmic knocking | Acceleration and high RPM | Critical – Stop immediately |

| Main Bearing Failure | Deep rumbling from bottom | Idle and low RPM | Critical – Professional help now |

| Piston Slap | Hollow knocking when cold | Cold startup | High – Schedule repair soon |

| Ring Flutter | Rapid chattering | During acceleration | High – Monitor closely |

If you notice any of these internal engine problems, avoid high RPM and heavy loads. Turn off air conditioning and other accessories to reduce engine stress. Drive directly to a qualified repair facility using the shortest route.

Ignoring these warning sounds is more expensive than getting immediate professional help. What might start as a bearing replacement could turn into a complete engine rebuild if you keep driving with these symptoms.

Cooling System Noise Troubleshooting

The cooling system in your Toyota makes specific sounds when it starts to fail. Recognizing these sounds can save you time and money. These cooling system problems often sound like serious engine damage. Knowing these sounds helps you fix issues before they cost a lot.

Your cooling system has many parts that make different noises. The water pump, radiator, thermostat, and cooling fans each have unique sounds when they fail. Knowing these differences helps you avoid unnecessary worry and find the right fix.

Water Pump Failure Detection

Water pump noise sounds like grinding, squealing, or rumbling from the front of your engine. These sounds get louder with engine RPM and might be with coolant leaks near the water pump.

A failing water pump bearing makes a grinding noise, unlike belt squealing. This noise gets louder when the engine is cold and gets a bit softer as it warms up. You might also see coolant puddles under your Toyota after parking.

Listen for rumbling sounds from behind the radiator. These sounds mean worn pump bearings or damaged impeller blades. Never ignore water pump noise, as it can cause severe engine overheating.

Thermostat and Radiator Issues

Radiator issues make gurgling or bubbling sounds when the engine cools down. These sounds mean air pockets or circulation problems in the cooling system.

A stuck thermostat makes gurgling sounds as coolant tries to flow through a blocked opening. You’ll hear these sounds near the upper radiator hose or thermostat housing.

Hissing sounds mean coolant leaks in the radiator or hoses. These leaks create steam when hot coolant meets engine parts. Address hissing sounds immediately to avoid overheating damage.

Cooling Fan Problem Identification

Effective cooling fan diagnosis means listening for mechanical and electrical fan problems. Mechanical fans may wobble, making irregular whooshing sounds or grinding noises from worn bearings.

Electric cooling fans make different sounds when they fail. Motor whining means worn brushes or bearings, while clicking sounds come from faulty fan relays. Blade imbalance makes rhythmic whooshing that changes with fan speed.

Here are key cooling fan warning signs:

- Excessive noise during fan operation

- Intermittent clicking from the fan relay

- Grinding sounds when the fan starts

- Wobbling or vibration from the fan assembly

Always allow your engine to cool completely before checking cooling system parts. Hot coolant can cause severe burns, so safety is key during any cooling system check.

Fuel System Noise Analysis

Toyota owners need to know the difference between normal sounds and problems. Your car’s fuel system makes certain noises when it’s working right. But, some sounds mean trouble is coming.

Issues with fuel system parts can make your engine noisy. This can hurt your Toyota’s performance.

Fuel injectors that clog or malfunction cause uneven fuel delivery. This leads to poor engine performance and strange noises. Problems with the fuel pump or filter also cause unusual sounds that need fixing.

Identifying Normal and Problematic Clicking

Fuel injector noise sounds like rapid clicking from the engine bay. Normal clicking is soft and matches your engine’s RPM. This shows your fuel is being delivered correctly.

But, if the clicking is loud and irregular, it’s a sign of trouble. Clogged injectors make a louder, erratic clicking that changes with engine load. You’ll notice this abnormal clicking most when you accelerate or when your engine works harder.

Failed injectors don’t click at all. This means they need to be replaced right away. Listen at idle to find out which cylinders might be silent or weak.

Recognizing Pump Operation Issues

Fuel pump whining happens when the pump can’t get enough fuel pressure. A normal pump hums quietly, almost inaudibly inside your car. This quiet sound means the pump is working well.

But, if the pump whines loudly or grinds, it’s a problem. You’ll hear this sound when your fuel tank is half-empty or lower. The whining gets louder when you accelerate.

A failing pump makes an intermittent whine. This pump noise often happens before the pump fails completely and stops delivering fuel.

Understanding Fuel Quality Related Knocking

Carbon knock sounds like pinging or knocking when you accelerate. It’s caused by using the wrong octane fuel or too much carbon in your engine. This noise happens when you’re climbing hills or accelerating hard.

Using low-quality fuel leads to pre-ignition and knocking. This disrupts your engine’s timing, causing the pinging sound. This fuel-related knocking is different from mechanical knock in how it sounds and when it happens.

Fixing fuel system problems means testing fuel pressure, injector spray patterns, and fuel quality. Professional cleaning can solve minor issues. But, serious cases might need replacing parts and a full fuel system overhaul.

DIY Solutions for Minor Toyota Engine Noise Problems

Toyota owners can fix many noise issues with basic automotive repair skills. Most noises come from neglecting simple maintenance, not serious problems. Doing these fixes yourself saves money and helps you understand your car better.

Regular Toyota maintenance stops most noise problems before they cost a lot. Simple tasks like oil changes and belt replacements often solve annoying sounds. Catching problems early makes these DIY solutions work best.

Performing Oil Change and Filter Replacement

A DIY oil change fixes one of the most common engine noise causes in Toyotas. Old or dirty oil causes friction, leading to knocking and grinding sounds. Fresh oil with the right viscosity reduces noise a lot.

Dirty oil filters block oil flow to engine parts. This restriction causes wear and unusual sounds. Replacing the filter with each oil change ensures clean oil reaches all parts.

Required Tools and Materials

Get these essential items for your DIY oil change:

- Socket set with ratchet handle

- Oil drain pan (6-quart capacity minimum)

- Oil filter wrench

- Funnel for adding new oil

- Jack and jack stands for vehicle lifting

- Disposable gloves and safety glasses

Buy the correct oil type and amount for your Toyota. Check your owner’s manual for viscosity. Most Toyotas need 4-6 quarts of oil, depending on engine size.

Choose a quality oil filter for your vehicle’s year and engine type. Generic filters may not filter well, leading to engine wear. OEM or equivalent filters fit and perform right.

Step-by-Step Procedure

Warm your engine for 3-5 minutes to thin the oil. Turn off the engine and let it cool for 10 minutes. Place your drain pan under the oil drain plug before loosening it.

Remove the drain plug with your socket set and let oil drain completely. This takes 15-20 minutes. Clean the drain plug and check the gasket for damage while waiting.

Find the oil filter and place your drain pan underneath it. Use the oil filter wrench to remove the old filter, turning counterclockwise. Expect additional oil to spill out when the filter comes free.

Apply a thin layer of new oil to the rubber gasket on the new filter. Install the new filter by hand until the gasket contacts the mounting surface. Tighten an additional 3/4 turn by hand only.

Reinstall the drain plug with a new gasket if needed. Tighten to manufacturer specifications, typically 25-30 foot-pounds. Add new oil through the filler cap using your funnel.

Start the engine and let it run for 5 minutes to circulate new oil. Check the oil level with the dipstick and add more if necessary. Inspect under the vehicle for leaks before driving.

Replacing Worn Belts

Belt replacement stops squealing, chirping, and grinding noises from the engine bay. Worn belts slip on pulleys, causing annoying sounds during acceleration. Cracked or frayed belts can break suddenly, leaving you stranded.

Modern Toyota vehicles use a single serpentine belt to drive multiple accessories. This belt powers the alternator, power steering pump, air conditioning compressor, and water pump. Regular inspection prevents unexpected failures.

Signs of belt wear include visible cracks, fraying edges, or glazed surfaces. A properly tensioned belt should not deflect more than half an inch when pressed. Replace belts showing any signs of deterioration.

Safety Precautions

Engine bay work requires careful attention to safety protocols. Always work on a cool engine to prevent burns from hot components. Disconnect the negative battery terminal before starting any automotive repair work.

Use proper jack stands to support the vehicle if you need to work underneath. Never rely on a jack alone for support. Keep loose clothing and jewelry away from moving parts and pulleys.

Wear safety glasses to protect your eyes from debris. Work gloves provide better grip and protect your hands from sharp edges. Have a flashlight or work light available for better visibility.

Installation Process

Locate the belt routing diagram, usually found on a decal in the engine bay. Take a photo with your phone as a reference before removing the old belt. This diagram shows the correct path around all pulleys.

Find the belt tensioner pulley and use the appropriate tool to release tension. Most Toyota tensioners use a 3/8-inch square drive or specific-sized socket. Rotate the tensioner to create slack in the belt.

Remove the old belt by sliding it off the pulleys while maintaining tension relief. Inspect all pulleys for damage or excessive wear. Clean any debris from the pulley grooves before installation.

Route the new belt according to the diagram, ensuring it sits properly in all pulley grooves. The ribbed side should contact the grooved pulleys. Double-check the routing before releasing the tensioner.

Release the tensioner slowly to apply proper tension to the new belt. Start the engine and listen for unusual noises. A correctly installed belt runs quietly without slipping or squealing.

These Toyota maintenance tasks address many common engine noise complaints effectively. Regular oil changes and belt replacements keep your engine running smoothly and quietly. Master these skills to maintain your Toyota’s reliability and performance.

When Professional Help Is Needed for Toyota Engine Noise

Knowing when to stop DIY fixes and get professional help can save you a lot of money. Some Toyota engine noises can be fixed at home, but others need expert attention right away. Knowing the warning signs helps you make the right choice for your car.

It’s not always easy to know when to switch from DIY to professional help. But, some situations are clear and need a pro’s touch for your car’s health.

Warning Signs Requiring Immediate Attention

Some engine noises mean serious problems that need quick help. Sudden loud knocking sounds often mean big damage or bearing failure. This noise gets worse fast and can ruin your engine in minutes.

When you see the oil pressure light on and hear grinding, it’s an emergency. This could mean bearing seizure. Driving on could turn a small fix into a big engine job.

Grinding sounds and engine vibration mean timing chain failure or damage inside. These signs come on fast and need quick service to avoid more damage.

“When you hear sudden, loud knocking that wasn’t there yesterday, stop driving immediately. What might be a $500 repair today could become a $5,000 engine replacement tomorrow.”

Other warning signs include:

- Metal-on-metal scraping that increases with RPM

- Loud squealing accompanied by smoke from the engine bay

- Rhythmic banging that matches engine speed

- Any noise that causes the engine to stall or misfire

Selecting a Qualified Toyota Technician

Choosing the right Toyota technician is key for good repair and cost. ASE certification is a good start, but Toyota training is better for engine issues.

Look for techs with Toyota tools and parts. Independent shops can be cheaper than dealerships but need the right tools and training.

Ask for a written estimate before any work. A good pro will explain the diagnosis, give a cost breakdown, and offer a warranty.

When picking a service provider, consider:

- Toyota-specific experience and training credentials

- Access to factory diagnostic equipment

- Positive customer reviews and Better Business Bureau ratings

- Transparent pricing and warranty policies

- Clean, organized facility with modern equipment

Understanding Repair Costs and Timelines

Engine repair costs vary a lot. Knowing the prices helps you budget and avoid being pushed by service advisors.

Simple fixes like belt replacements cost $100-300 and take 1-2 hours. But, bigger issues like timing chain replacement can cost $800-2,000, depending on parts and labor.

| Repair Type | Typical Cost Range | Expected Timeline | Urgency Level |

|---|---|---|---|

| Belt Replacement | $100-300 | 1-2 hours | Moderate |

| Timing Chain Repair | $800-2,000 | 1-3 days | High |

| Valve Train Service | $400-1,200 | 4-8 hours | Moderate |

| Engine Bearing Replacement | $2,000-4,000 | 3-5 days | Critical |

| Complete Engine Rebuild | $3,000-6,000 | 1-2 weeks | Critical |

Major internal engine problems like bearing replacement or rebuilds are big investments. These repairs can cost as much as your car is worth, making quick diagnosis important.

Knowing how long repairs will take helps you plan. Most Toyota techs can give a good estimate after diagnosing.

Delaying repairs can make them much more expensive. A $200 belt replacement ignored today could turn into a $2,000 engine repair next month.

Conclusion

Your Toyota’s engine talks to you through sounds. Learning to understand these signals helps you keep your car in top shape. This guide teaches you to spot normal sounds and those that need fixing.

Regular engine care is key to a reliable car. Simple tasks like checking oil and listening for odd noises can prevent big problems. This care keeps your Toyota running smoothly and saves you money.

Acting fast when you hear engine noises is important. It saves money and keeps your car running well for a long time. Use this guide whenever you notice new sounds from your engine.

Trust your ears if something sounds off. They’re often the first to warn you of engine issues. With the steps in this guide, you can handle most engine noise problems.

Keep this guide close for future use. Your Toyota needs your attention to stay reliable. Acting quickly on unusual engine noises protects your investment and keeps you safe on the road.

FAQ

What are normal engine sounds I should expect from my Toyota?

Your Toyota engine should hum gently. You might hear slight clicking at idle and the cooling fan’s whoosh. Also, expect fuel injector clicking and the soft whir of the serpentine belt. These sounds should stay the same, not changing much with engine temperature or load.

How can I tell if my Toyota’s engine knocking is serious?

Serious knocking sounds like heavy banging that gets louder with RPM and load. If it’s with low oil pressure warnings, vibration, or always there, stop driving right away. Light pinging with low-octane fuel is less serious but should be checked.

What should I do if my Toyota engine makes noise only during startup?

Startup noises often mean oil circulation issues or worn parts. If the noise goes away as oil pressure builds, it might be normal. But if grinding or loud knocking lasts, get your Toyota checked fast. It could mean serious problems.

How do I check if my Toyota’s engine oil is causing the noise?

Check the oil level with the dipstick after it’s been off for a bit. Look for the right color (amber to light brown) and consistency (should flow well). Low or bad oil quality can cause noise and damage if not fixed quickly.

What does Toyota timing chain rattle sound like?

Timing chain rattle sounds like metallic rattling or chattering, noticeable at startup or idle. It’s usually from the front and may cause rough idling. This noise means stretched chains or worn tensioners and needs quick professional help to avoid engine damage.

When should I replace my Toyota’s serpentine belt to prevent noise?

Replace the belt if you hear squealing, chirping, or slapping, often at startup or with accessories on. Check for cracks, fraying, or wear. Most belts should be replaced every 60,000-100,000 miles or when showing signs of wear.

What causes valve lifter ticking in Toyota engines?

Valve lifter ticking is rapid clicking or tapping, more noticeable when cold. It’s usually from low oil pressure, dirty oil, worn lifters, or wrong oil viscosity. Regular oil changes and the right oil can prevent most issues. If ticking persists with fresh oil, get it checked by a pro.

How can I tell if my Toyota has serious internal engine damage?

Serious damage shows as heavy knocking that gets worse with RPM, deep rumbling, metal grinding, or knocking with oil pressure warnings. Stop driving if you hear these sounds. Ignoring them can lead to engine failure and expensive repairs.

What does a failing Toyota water pump sound like?

A failing water pump makes grinding, squealing, or rumbling sounds from the front, often with coolant leaks or overheating. The noise might be constant or only when running. Failure can cause overheating and damage if not fixed quickly.

Is fuel injector clicking normal in Toyota engines?

Some clicking is normal and means the injectors are working right. But too much clicking, irregular patterns, or changing with load might mean clogged or failing injectors. Normal clicking is soft and steady, while bad clicking is loud and uneven.

Can I fix minor Toyota engine noise issues myself?

Yes, you can handle some minor issues like oil changes and filter replacements. Make sure you have the right tools, follow safety, and use Toyota parts and fluids. But for timing chain, valve, or internal noise, get a pro to check and fix it.

When should I take my Toyota to a professional for engine noise?

Get professional help right away for loud knocking, no oil pressure, grinding with vibration, or worsening noise. Also, see a Toyota expert if you can’t find the noise source, simple fixes don’t work, or you’re not sure what to do.

How much should I expect to pay for Toyota engine noise repairs?

Costs vary a lot. Simple fixes like oil changes or belt replacements cost -200. But timing chain repairs can be 0-2,500. Major engine problems might cost ,000-8,000 or more. Always get written estimates and understand warranties before expensive repairs.

What Toyota models are most prone to specific engine noise issues?

Some Camry and RAV4 models have timing chain stretch issues. Prius models might have water pump noise. Corolla engines are usually reliable but can have valve train noise with poor care. Regular maintenance helps prevent most noise issues, no matter the model.

How can I prevent engine noise problems in my Toyota?

Prevent noise by changing oil regularly with the right grade, replacing belts and chains on time, keeping the cooling system up, and fixing unusual sounds fast. Quality fuel and regular maintenance are key to avoiding engine noise.